Unplanned downtime creates your single largest hidden cost in industrial filtration. The financial impact across manufacturing is significant, with some industries losing millions per hour.

| Category | Average Annual Cost |

|---|---|

| Overall Manufacturers | $255 million |

| Automotive Industry (hourly) | Over $2 million |

| Oil & Gas Operations (hourly) | Nearly $500,000 |

You can reduce these expenses. Extending filter life and simplifying maintenance are the keys to success. Advanced media, like the POXL filter bag or a custom filter bag, directly translates to lower operational costs and higher output.

The Hidden Costs of Conventional Filtration

Conventional filtration methods often create expenses that go beyond the initial purchase price. You might see these costs in your budget as production downtime, high labor fees, and unpredictable performance. Understanding these hidden expenses is the first step toward improving your bottom line.

Frequent Changeouts and Production Halts

You must stop production to change a filter. Standard filters in high-load applications can clog quickly. There is no exact timeline for a filter’s life. Its lifespan depends on your system, the materials you filter, and the dirt load. You know it is time for a replacement when the pressure differential increases.

Pro Tip: A pressure differential reaching 15 psid usually means your filter bag is full. Constant monitoring is necessary to avoid system failure, but this reactive approach leads to frequent and unplanned production halts.

High Labor and Disposal Expenses

Each filter changeout requires manual labor. Your team spends valuable time removing the old filter, installing a new one, and restarting the system. These labor hours add up significantly over a year. You also face rising disposal costs. Used filters are industrial waste, and their disposal must comply with environmental regulations, adding another layer of expense. More frequent changeouts directly translate to higher labor and disposal bills.

Inconsistent Filtration Performance

You need consistent results for a quality end product. Conventional filtration can be unreliable. Performance can vary due to several factors:

- Changes in your raw material quality.

- Shifts in process temperature or flow rates.

- An undersized filtration system.

- Damaged or collapsed filters that allow bypass.

These issues create unpredictability. You may experience lower flow rates or poor contaminant capture. This inconsistency forces you to conduct extra quality checks and can even lead to product rejection, directly impacting your profitability.

How the POXL Filter Bag Cuts Costs and Downtime

Switching to an advanced filtration solution like the POXL filter bag from Precision Filtration is a direct strategy for improving your operational budget. You can move from a reactive maintenance cycle to a proactive, cost-saving model. This technology is engineered specifically to combat the hidden costs of conventional filters.

Superior Construction for Longer Service Life

You can extend the time between filter changeouts significantly. The POXL filter bag achieves a service life up to five times longer than standard felt bags. This durability comes from its advanced design and materials.

- Proprietary Fiber Blend: The media uses a heavier, thicker, and stronger fiber blend. This enhances filtration efficiency without increasing the initial pressure on your system.

- Fully Welded Construction: For critical processes, you can choose fully welded bags. Ultrasonic welding creates impenetrable seams, which eliminates the risk of bypass through needle holes found in sewn bags.

- Special Heat Treatment: A glazed finish on the material prevents fibers from breaking off and migrating into your final product, ensuring purity.

These features work together to create a robust filter that resists wear and tear, directly reducing the frequency of production shutdowns for maintenance.

Increased Dirt-Holding Capacity Boosts Efficiency

You get more value from each filter because it holds more contaminants. The POXL filter bag features a unique needle felt construction that doubles the internal pore space. This gives it two to four times the dirt-holding capacity of conventional filters.

The filter media uses a graded-density structure. Think of it as a multi-stage net:

- The outer layers have larger pores to capture bigger particles.

- The inner layers have progressively smaller pores to trap finer contaminants.

This depth-loading design uses the entire filter media, not just the surface. Your filter captures more dirt before it clogs, maintaining a steady flow rate and consistent performance for a longer period. This means fewer changeouts, less waste, and a more efficient production line.

Simplified Installation Reduces Maintenance Time

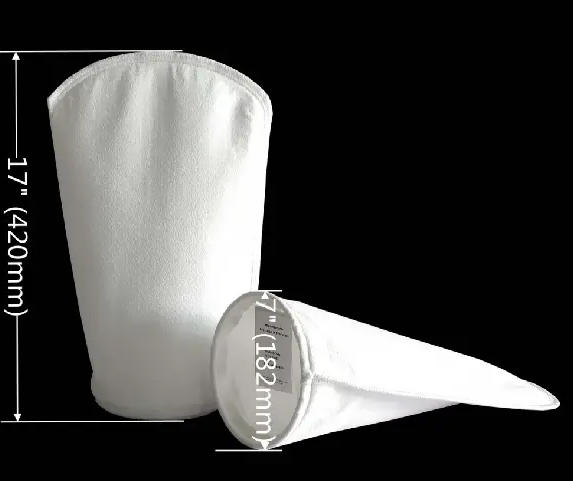

You can make filter changeouts faster and safer for your team. The POXL filter bag is designed for user-friendliness. Many models feature a durable plastic flange with integrally molded handles.

Maintenance Tip: The built-in handles give your technicians a secure grip, making it easy to pull the used bag out of the housing without extra tools or effort. This simple design feature reduces the time spent on each changeout and minimizes worker contact with filtered materials.

This streamlined process cuts down on labor hours. Your team can complete maintenance tasks more quickly and get the production line running again with minimal delay.

Lower Energy Use from Reduced Differential Pressure

You can lower your facility’s energy bill. A pump must work harder to push liquid through a clogged filter, consuming more electricity. Because the POXL filter bag has a higher dirt-holding capacity, it takes much longer to reach a high differential pressure.

The filter’s advanced media maintains a lower pressure drop from the start and throughout its extended life. This means your system pumps operate with less strain. Less strain equals lower energy consumption. For large industrial systems, these savings add up quickly.

| System Type | Potential Annual Savings |

|---|---|

| Large HVAC System | ~$33,000 |

| Compressed Air System | ~€1,460 (~$1,550) |

By reducing the workload on your pumps, you not only save on energy costs but also reduce wear and tear on critical equipment, further lowering long-term operational expenses.

Adopting POXL technology is your strategic investment in operational reliability. The long-term savings in labor, energy, and materials far outweigh the initial cost of the filter bag. Upgrading your filtration system is a critical step toward a more profitable and efficient 2026, ensuring you stay ahead.

FAQ

Will the POXL filter bag fit my current system?

You can use POXL bags in most standard filter housings. Precision Filtration also creates custom bags to match your exact equipment specifications for a perfect fit.

Is the POXL bag safe for food and beverage use?

Yes, it is safe. The POXL filter bag uses silicone-free, FDA-compliant materials. This makes it an excellent choice for your food, beverage, and other sensitive applications.

What if I cannot allow any filter bypass?

You can choose fully welded bags for absolute reliability. This design eliminates sewing holes, preventing any bypass and ensuring 100% of your product flows through the filter media.

Post time: Nov-17-2025