Using filter bags and bag filter systems is one of the most efficient ways to remove contaminants and particulates from liquids in industrial applications. However, even the best filter bags need timely replacement to maintain top performance. If not properly maintained, worn-out filter bags can lead to system damage, production slowdowns, and costly blockages.

Precision Filtration specializes in bag filter systems and advanced industrial filtration solutions. Here’s how to recognize when to replace your filter bag, what factors affect its lifespan, and what to consider when selecting a new one.

How Long Do Industrial Filter Bags Last?

There isn’t a one-size-fits-all answer to this question. The lifespan of a filter bag depends on several factors, including:

System design and operating requirements

Type of liquid and contaminants being filtered

Filtration degree (micron rating)

Dirt load and flow rate

Because these factors vary widely, monitoring your filter bag’s performance is essential. Replacing the filter bag promptly when it begins to lose efficiency helps keep your system running smoothly and prevents costly downtime.

Signs It’s Time to Replace Your Filter Bag

The most reliable indicator that your filter bag needs replacement is an increased pressure differential. Over time, filter bags collect debris and become clogged, making it harder for liquid to pass through.

Keep an eye on the pressure drop across your filter housing:

A clean filter bag typically operates at 2–3 PSID.

Once the differential pressure reaches 15 PSID, the bag is considered dirty and should be replaced.

This value can vary based on the viscosity of the liquid, the filtration level, and the specific system design. Regular monitoring ensures your filtration process stays efficient and prevents system strain.

Key Factors to Consider When Choosing a Replacement Filter Bag

Selecting the right replacement filter bag depends on multiple variables. To make the best choice for your bag filtration system, evaluate the following:

Type and size of contaminants or solids to remove

Material compatibility with the filtered liquid

Flow rate, pressure, temperature, and overall process conditions

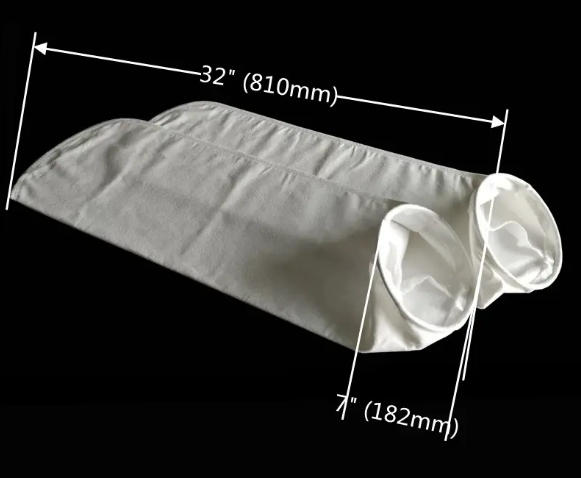

Filter housing design and size

Desired micron rating

By considering these elements carefully, you can extend the life of your filtration system and maintain consistent performance.

Your Trusted Partner for Bag Filter Systems and Industrial Filtration

Whether you’re determining the right time to replace a filter bag, selecting a suitable replacement, or optimizing your overall bag filtration system, Precision Filtration provides the products and expertise you need.

With extensive experience in industrial filtration solutions, we deliver reliable filter bags, housings, and system components that keep your operation efficient and contaminant-free.

Contact Precision Filtration today to find the ideal filtration solution for your industrial application.

Post time: Nov-04-2025