1. What is a Fleece Bag Filter?

1.1. Core Definition

A Fleece Bag Filter is a highly efficient medium primarily constructed from synthetic non-woven materials such as fleece or felt. It utilizes a dense network of fibers to physically intercept and capture fine particles, dust, or debris from either air or liquid streams through the principle of mechanical filtration. This material is increasingly replacing traditional paper or mesh media in various professional fields due to its superior toughness and consistent filtering performance.

1.2. The Core Principle: Mechanical Filtration

Mechanical filtration is the core operational method of the fleece filter bag. As contaminant-laden fluid (air or water) is forced through the bag, the fiber structure creates a physical barrier. Solid contaminants larger than the pore size are directly intercepted on the surface (sieving effect), while smaller particles are trapped within the fibers through inertial impaction, diffusion, and adhesion, effectively purifying the fluid stream.

1.3. Two Primary Applications

Despite the shared name, fleece filter bags are critical components in two distinct markets: industrial and professional-grade vacuum cleaners (for dust collection), and aquarium/pond systems (for water body filtration).

2. Application 1: Fleece Bags for Vacuums & Dust Extractors

2.1. What Are They?

In workshop or construction environments, fleece filter bags serve as the primary debris collection medium in high-performance wet/dry vacuums and professional dust extraction systems. They directly replace fragile, less breathable traditional paper dust bags, ensuring the vacuum maintains optimal performance even when dealing with heavy or damp materials.

2.2. Key Materials

Fleece bags for vacuum cleaners are typically constructed from a multi-ply (standard 3 to 5 layers) composite of highly tear-resistant polypropylene or polyester non-woven fabric. This multi-layer structure is crucial: the outer layer usually provides mechanical strength and coarse pre-filtration, preventing the bag from being pierced by sharp objects; the inner layers utilize finer melt-blown materials to offer superior dust retention and particulate filtration, thus extending the life of the main vacuum filter.

2.3. How They Work

When the vacuum is turned on, the resulting strong negative pressure draws air and dust into the bag. The porous nature of the fibers inside the bag, coupled with the multi-layer depth filtration effect, allows it to effectively capture contaminants ranging from fine sawdust and drywall dust to general debris, while allowing relatively clean air to pass through for exhaust or secondary filtration.

2.4. Key Advantages Over Paper Bags

Fleece filter bags offer overwhelming performance advantages for professional users:

- Extremely Tear-Resistant: Fleece material possesses exceptional flexibility and strength, rarely tearing or bursting even when sharp, heavy construction debris like nails, broken glass, or stones are suctioned. This guarantees a clean working environment and operator safety.

- Higher Dust Retention Rate: The multi-layer construction achieves much finer filtration. For fine dust, the filtration efficiency of fleece bags is far superior to single-layer paper bags, effectively protecting the vacuum’s main filter (like a HEPA cartridge) and extending its lifespan.

- More Capacity / Longer Suction: Paper bags quickly clog on the surface as dust accumulates, leading to a dramatic drop in suction power. Fleece bags, however, utilize depth filtration, storing dust throughout multiple layers of fibers, thus maintaining near-constant suction even when the bag is almost full.

- Moisture-Resistant: Unlike paper bags which disintegrate upon contact with moisture, synthetic fleece maintains its structural integrity even when small amounts of water or damp debris are vacuumed, making it ideal for wet/dry shop vacuums.

- Protects the Motor: The superior dust retention means fewer fine particles reach the motor, significantly reducing motor wear and maintenance needs.

- Lower Total Cost of Ownership (TCO): For professional cleaning services or facilities, longer replacement intervals (due to sustained suction) and enhanced motor protection directly translate into less downtime, reduced labor costs, and lower capital expenditure on equipment maintenance, resulting in a lower overall operational cost in the long run.

2.5. Types: Disposable vs. Reusable

Most fleece filter bags are designed for single-use, prioritizing hygiene and convenience. Once full, they can be sealed and discarded directly, minimizing user exposure to dust. However, “permanent” or reusable fleece bags also exist in the market, often equipped with zippers or clips that allow the user to empty the collected debris and reuse the bag. While the latter reduces consumables costs, it requires more maintenance time and increases the risk of dust exposure.

2.6. Installation & Replacement

Installation is typically straightforward: open the vacuum canister, align the bag’s rigid cardboard or plastic collar (flange) with the vacuum’s internal intake port, and push it in. The collar usually includes a rubber gasket to ensure a tight seal and prevent dust leakage. When replacing, the entire bag is cleanly removed by pulling out the sealed collar.

2.7. Common Brands & Compatibility

Bags on the market are typically designed for specific models from major brands (e.g., Kärcher, Fein, Flex, Festool, Bosch, Makita). For B2B procurement, selecting a bag that is precisely compatible with the existing equipment model is crucial. As a manufacturer, we offer cross-brand compatible or custom collar designs to fit a variety of machinery.

2.8. Critical Compliance: M, L & H-Class Filtration

For professional industrial and construction sectors, dust is not just a cleanliness issue—it’s a matter of worker safety and legal compliance. Fleece filter bags are adept at meeting stringent international standards for dust collection:

- L-Class (Low Risk): Suitable for general, non-hazardous dusts. Fleece bags commonly meet this requirement.

- M-Class (Medium Risk): Required for moderately hazardous dusts like wood chips, filler, plaster, and silica dust. Many high-quality multi-layer fleece bags, when used with M-Class certified vacuums, can meet the M-Class standard, requiring over 99.9% filtration efficiency. This is the most common mandatory compliance level in the construction and woodworking industries.

- H-Class (High Risk): Necessary for highly hazardous dusts such as asbestos, mold spores, and carcinogenic dusts.

For purchasers, selecting a fleece bag product line that meets M-Class or H-Class requirements is a crucial strategy that transforms “consumables procurement” into a “safety investment” and a key way to mitigate legal fine risks. Our products focus on providing filter media that conforms to these strict standards, helping clients achieve worry-free compliance.

3. Application 2: Fleece Bags for Aquariums & Ponds

3.1. What Are They?

In the aquatic sector, fleece filter bags are commonly known as “Filter Socks.” They serve as highly efficient mechanical pre-filters installed at the drainage point of an aquarium’s sump or overflow box. They are the first line of defense in the tank’s filtration chain, designed to remove all visible suspended particulate matter from the water, setting the stage for subsequent biological and chemical filtration stages.

3.2. Key Materials

Aquarium filter socks are typically manufactured from polypropylene or polyester materials. Unlike the vacuum bags which emphasize tear resistance, filter socks prioritize structural stability and chemical inertness in water.

- Material Properties: Chemical Inertness & Food-Grade Safety

Filter bag materials for aquatic and food processing applications must be chemically inert, meaning they will not leach any harmful chemicals, dyes, or toxins when submerged for extended periods, thus guaranteeing the safety of the water environment. The raw materials for many high-quality filter socks even meet Food-Grade standards, ensuring absolute safety in sensitive environments like aquaculture.

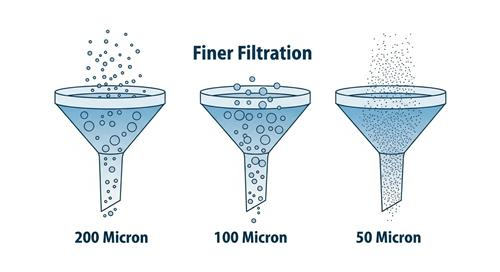

3.3. The Key Concept: Micron Rating

The Micron Rating is the single most critical specification for an aquatic filter sock, directly defining its filtration fineness. One micron equals one-millionth of a meter.

- 50 Micron: Extremely fine filtration, used for “Water Polishing.” It effectively removes tiny particles that are barely visible to the naked eye, making the water crystal clear, but it tends to clog very quickly.

- 100 Micron: The most common general-purpose rating. It removes most visible suspended matter while maintaining good flow rates, making it ideal for reef tanks and heavily stocked fish tanks.

- 200 Micron: Coarse filtration, used for removing large food debris or plant matter, offering the longest replacement interval and maximum water flow throughput.

For aquarium system designers or equipment suppliers, providing a range of micron ratings is vital, allowing customers to select the most suitable filtration solution based on their tank type, biological load, and maintenance frequency.

3.4. How They Work

Aquatic filter socks use gravity or pump pressure to direct the water flowing down from the aquarium’s overflow through the bottom and sides of the sock. The sock physically removes all suspended organic and inorganic particles—food residue, fish waste, algae fragments, and shedding skin—before these contaminants can decompose and convert into harmful nutrients like nitrate and phosphate.

3.5. Advantages

Aquatic filter socks are essential for maintaining high-quality water parameters:

- Improves Water Clarity: Filter socks are the best tool for achieving “water polishing.” By removing micro-particulates, they dramatically reduce haze in the water, making the aquarium look more professional and visually sharp.

- Nutrient Control: The physical removal of organic waste is one of the most effective ways to control the rise of nutrients in an aquarium. Eliminating waste before it begins to decompose is key to maintaining healthy corals and reducing unwanted algae blooms.

- Protects Equipment: Socks intercept coarse debris, preventing them from entering expensive sump equipment like return pumps, heaters, or protein skimmers, thereby prolonging their lifespan and maintaining operational efficiency.

- Versatility: They can easily be used to hold additional chemical filtration media (like activated carbon or resins), enabling multi-functional filtration in a single location.

3.6. Disadvantages & Maintenance

The main drawback of filter socks is their maintenance intensity. Because they are designed to trap particles, they clog quickly—especially finer 50-micron socks, which may require changing every 2-4 days. If clogged, water will overflow the top (bypassing the filter), causing filtration failure, while the accumulated waste inside the sock rapidly decomposes and leaches nitrates into the water. To address this pain point, automated solutions like Automatic Fleece Rollers have emerged, which use rolling fleece media to replace the hassle of manual sock changes.

3.7. Maintenance: Cleaning vs. Replacing

Many aquarists clean their filter socks to save costs. The cleaning process involves turning the sock inside out to remove bulk debris, then soaking it in a bleach solution for disinfection, followed by a thorough rinse to remove all chemical residue, or running it through a washing machine separately. However, the fiber structure degrades over time, and the bag’s efficiency will decrease. The sock should be discarded and replaced when it starts to fray or cannot be fully cleaned.

3.8. Beyond the Aquarium: Industrial Liquid Filtration Applications

The powerful function of filter socks extends far beyond the home aquarium. In industrial settings, felt/fleece filter bags are the core component of Bag Filter Systems, widely used in:

- Aquaculture: Employed in commercial fish and shrimp farms to remove large volumes of organic waste and feed remnants, maintaining stable water quality to optimize growth environments.

- Pools & Spas: Used as pre-filtration or main filtration to capture fine algae and sediment, reducing the load on chemical disinfectants.

- Food & Beverage Processing: Used to clarify liquids such as juices, beer, or cooking oils, removing suspended impurities to ensure the clarity and purity of the final product.

- Chemical Filtration for Plating: Used in metal plating processes to filter solid particles from the plating solution, preventing surface defects on the finished products.

These applications collectively demonstrate the fleece filter material’s high efficiency, high load capacity, and cost-effectiveness in diverse and complex liquid purification tasks, making it an ideal choice for industrial purchasers seeking advanced liquid filtration solutions.

4. For B2B Partners: Customization & Procurement

4.1. OEM/ODM Services: Build Your Brand

As a specialized manufacturer of fleece filter bags, we understand the importance of branding and precise specifications for distributors and equipment manufacturers. We offer comprehensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services to integrate your brand identity into the product.

- Precise Size and Shape Customization: Whether you require a bag for a specific industrial vacuum model (e.g., with a unique oval collar) or a non-standard liquid filtration vessel, we can execute precise size and shape customization based on your CAD drawings or physical samples.

- Collar/Flange Types: We offer various collar materials and color options, including PP (Polypropylene), PVC, stainless steel, or custom cardboard, to ensure perfect compatibility with your client’s equipment.

- Branding and Packaging: We can directly print your company logo on the bag’s collar or label, and design custom color box packaging, multilingual manuals, or barcodes to ensure your branded product stands out with professionalism in the market.

4.2. Deep Dive: Material & Spec Customization

The core of filtration performance lies in the raw material. We offer in-depth material customization tailored to specific application scenarios, meeting clients’ stringent performance requirements:

- Material Type Differentiation:

Spunbond: High strength, good abrasion resistance, often used for the outer layer of vacuum bags, providing structural support and coarse pre-filtration.

Melt-blown: Extremely fine fibers with small pores, suitable for the fine filtration layers, used to achieve high micron rating efficiency (e.g., 50 micron).

Needle-Punched Felt: Features greater thickness and volume, offering excellent depth filtration capability and high dust/particle holding capacity, commonly used in industrial liquid bag filtration.

- Key Specification Customization:

GSM (Grams per Square Meter): Affects material thickness, strength, and filtration resistance. We can adjust GSM to balance strength with airflow/liquid flow rate.

Thickness: Influences the bag’s depth filtration capacity and service life.

Micron Rating: In liquid filtration, we can precisely control the material’s micron rating, ranging from 1 micron to 200 micron, to meet various liquid clarification needs.

Special Treatments: We offer anti-static treatment (for vacuum bags, mitigating dust explosion risk) and anti-microbial treatment (for aquatic or food applications).

Through customization services, we ensure your branded filter bags achieve the optimal configuration in terms of both performance and cost-effectiveness.

4.3. Quality Assurance & Supply Chain

Superior quality is the foundation of any B2B partnership. Our quality management system adheres to international standards, and all filter bag products undergo a rigorous Quality Control (QC) process, ensuring high consistency in dimensional accuracy, material integrity, and filtration efficiency across every batch.

- Compliance and Certification: We provide relevant ISO certification documents and Material Safety Data Sheets (MSDS), guaranteeing that the product meets regulatory requirements in the client’s market, especially M-Class or Food-Grade standards in Europe and North America.

- Supply Chain Optimization: We have established an efficient global logistics network capable of handling bulk orders of various scales. Our Minimum Order Quantity (MOQ) is flexible, designed to support the diverse needs of clients ranging from small-scale distributors to large OEM customers.

- Transparent Lead Time: We offer transparent production and shipping schedules, working closely with clients to develop inventory and dispatch plans that minimize the client’s risk of stock shortages and ensure the timeliness and stability of supply.

Choosing us means choosing a supply chain partner that provides high-quality, compliant, and logistically reliable products.

5. Conclusion & FAQ

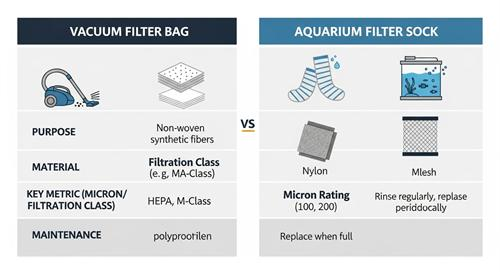

5.1. Comparison Chart: Vacuum vs. Aquarium

The fleece filter bag plays a crucial role in both sectors, though its design and key metrics differ.

5.2. Summary: Why Choose a Fleece Bag Filter?

English: The fleece filter bag represents a significant advancement in mechanical filtration technology. It offers a unified promise across two distinct fields: higher efficiency, longer service life, and superior tear resistance. Whether protecting workers’ lungs and equipment in a workshop or achieving water polishing in an aquarium, fleece is the professional-grade filter medium of choice.

5.3. FAQ

Can fleece bags handle liquids?

A: Only bags specifically designed for liquids (i.e., aquatic or industrial socks, typically Polypropylene/Polyester) should be used for liquid filtration. Vacuum bags, while moisture-resistant, are not intended for prolonged immersion or filtering large liquid volumes.

What is the micron rating of fleece bags?

A: Vacuum bags are typically measured by filtration class (L, M, or H) and usually filter down to below 5-10 microns. Aquatic bags are measured by a precise micron value (e.g., 50, 100, 200 microns).

Can you manufacture a custom bag for my vacuum model?

A: Yes, we offer full OEM/ODM services. Simply provide the equipment model or interface specifications, and we can customize the interface collar and material to your exact fit.

What is your Minimum Order Quantity (MOQ)?

A: Our MOQ is flexible, depending on the complexity of the customization and the material. Please contact our sales team directly for a detailed quotation and quantity requirements tailored to your specific needs.

Post time: Nov-07-2025