Nylon filter bag and polyester filter bag differ in material, construction, and performance. Each type offers unique benefits for liquid filtration. Selecting the correct bag filter media impacts filtration efficiency and long-term results. The right choice helps users achieve the best outcome for their specific application. Bag filter media can improve product quality and process reliability.

What Is a Nylon Filter Bag

Nylon Filter Bag Material and Construction

A nylon filter bag stands out in industrial filtration because of its unique material properties and construction. Manufacturers use high-quality nylon monofilament mesh to create these bags. This mesh features precise weaving, which ensures consistent pore sizes and reliable filtration. The construction provides excellent strength and durability, making the nylon filter bag suitable for demanding environments.

The following table highlights the main material properties that distinguish nylon filter bags from other types:

| Property | Details |

|---|---|

| Ideal Use | Economical Chemical and Mild Media Filtration |

| Compatible With | Organic Solvents, Oils, Microorganisms, Alkalies |

| Incompatible With | Oxidizing Agents, Mineral Acids, Inorganic Acids |

| Temperature Rating | 0-325°F |

| Micron Rating | 5 µm to 1,000 µm |

| Construction Types | Nylon Monofilament Mesh, Multifilament Mesh |

| Other Key Features | FDA Food-Grade, Cleanable / Reusable, High Tensile Strength |

Nylon filter bags resist tearing and abrasions. This quality makes them ideal for industrial filtration where harsh conditions often occur. The tightly woven mesh allows for higher flow rates, which improves efficiency in many industrial filtration processes.

Key Features and Benefits

Nylon filter bags offer several features and benefits that make them a preferred choice in industrial filtration:

- Superior strength and durability support long-term use.

- Good abrasion and wear resistance help maintain performance in tough environments.

- Excellent chemical and thermal stability allows use in moderate chemical exposure.

- Low friction and smooth surface properties ensure efficient fluid flow.

- Versatility in applications includes water treatment, chemical processing, and industrial manufacturing.

Manufacturers like Precision Filtration provide nylon filter bags in standard and custom sizes. Multiple sealing options, such as Ring Top and Plastic Flange, increase compatibility with various housings. These bags are reusable, which helps reduce costs over time.

Nylon filter bags also meet FDA regulations for food and beverage applications. They undergo rigorous testing for air permeability and strength. Each bag is individually sealed in protective packaging to maintain purity and prevent contamination.

Tip: Nylon filter bags work well for both high viscous liquids and general industrial filtration tasks. Their reusability and compliance with food-grade standards make them a reliable choice for many industries.

What Is a Polyester Filter Bag

Polyester Filter Bag Material and Construction

Polyester filter bags play a vital role in industrial filtration. Manufacturers use polyester fibers to create these bags, which offer a balance of strength and flexibility. The construction process involves weaving or felting polyester fibers into a durable fabric. This method produces a filter bag that can withstand high flow rates and pressure without tearing.

Polyester filter bags show excellent resistance to abrasion. They maintain their shape and size even when exposed to high temperatures. Most polyester filter bags operate at temperatures up to 275°F, with short surges reaching 300°F. These bags work best in dry conditions with low acids and alkalis. They are not recommended for moist or highly humid environments.

The following table summarizes the primary material characteristics of polyester filter bags:

| Characteristic | Description |

|---|---|

| Filtration Efficiency | High, effective for fine particles and dust |

| Tensile Strength | Excellent, resists tearing under pressure |

| Abrasion Resistance | Excellent, withstands wear in industrial use |

| Dimensional Stability | Maintains shape under heat, low shrinkage |

| Ease of Cleaning | Can be cleaned and reused, but repeated cleaning may affect performance |

| Service Life | Long, reduces need for frequent replacement |

| Maintenance | Easy, lowers maintenance costs |

| Versatility | Available in many sizes and shapes |

| Cost Effectiveness | Affordable compared to other materials |

Note: Polyester filter bags are widely available and offer a cost-effective solution for many industries.

Key Features and Benefits

Polyester filter bags deliver several important features and benefits. Their loose fiber structure increases impurity holding capacity, which improves filtration efficiency. These bags use a dual-stage filtration mechanism. Surface filtration captures larger particles, while depth filtration traps finer contaminants.

- Enhanced impurity capacity supports efficient filtration.

- Dual-stage filtration mechanism improves particle removal.

- Durability under pressure ensures consistent performance.

- Excellent tensile strength and oxidation resistance increase lifespan.

- Easy maintenance helps reduce operational costs.

Polyester filter bags are primarily designed for single use. Cleaning and reusing these bags may damage the material, which can affect filtration performance. Damage may cause enlarged pores or shrinkage, leading to quicker plugging or reduced efficiency.

Tip: Polyester filter bags work best in dry environments and provide reliable filtration for dust, fine particles, and industrial applications.

Key Differences in Bag Filter Media

Filtration Efficiency

Filtration efficiency plays a crucial role in determining the effectiveness of bag filter media. Polyester filter bags excel at fine particulate removal, capturing particles as small as 1 micron. Nylon filter bags perform well with larger particles, making them suitable for applications that do not require ultra-fine filtration. The following table compares the filtration efficiency and particle size range for both materials:

| Material | Filtration Efficiency | Particle Size Range |

|---|---|---|

| Polyester | Excellent (down to 1 micron) | 1 to 800 microns |

| Nylon | Good (larger particles) | 1 to 100 microns |

Polyester filter bags deliver high efficiency in fine particulate removal, which is essential for industries that demand optimal filtration results. Nylon filter bags provide reliable efficiency for general filtration tasks, especially when high dirt-holding capacity is needed. Both types of bag filter media contribute to the removal of contaminants, but polyester stands out for applications requiring precise filtration efficiency.

Temperature and Chemical Resistance

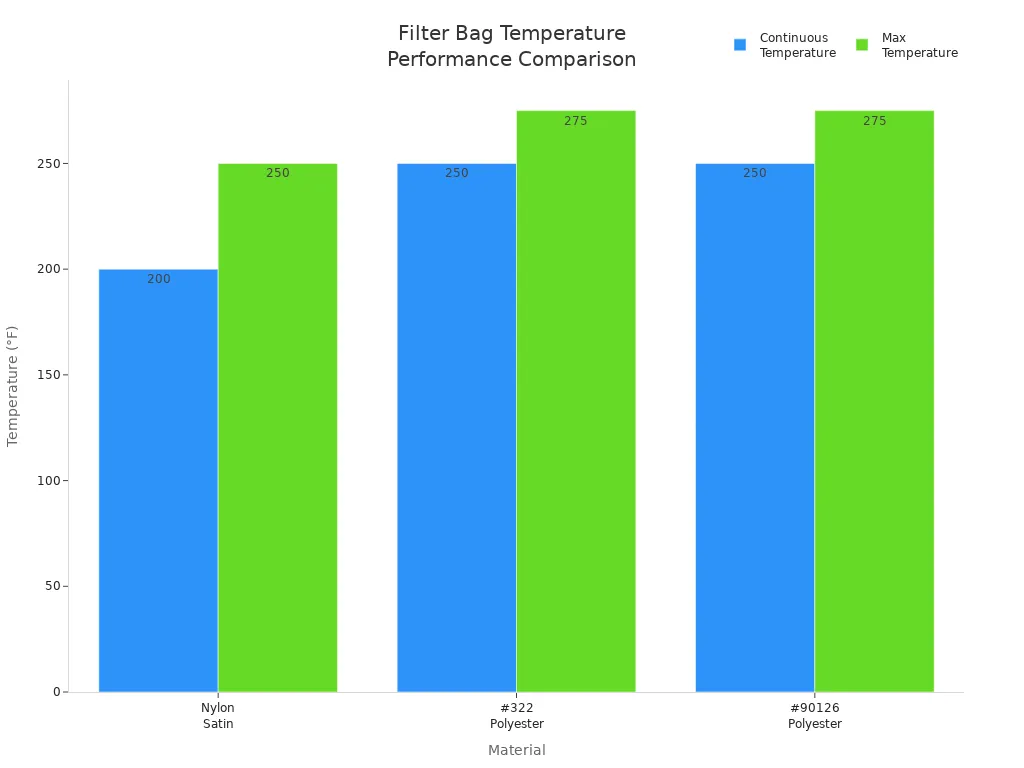

Temperature and chemical compatibility are important factors when selecting bag filter media. Polyester filter bags withstand higher temperatures, operating continuously at 250°F and reaching a maximum of 275°F. Nylon filter bags function well up to 200°F for continuous use, with a maximum of 250°F. The chart below illustrates the temperature ratings for both materials:

Polyester filter bags perform best in dry heat installations. In moist environments, especially at temperatures between 160°F and 210°F, polyester may experience hydrolysis, which can weaken the fabric. Nylon filter bags offer strong chemical compatibility with weak acids and alkalies, but they are not recommended for strong acids or oxidizing agents. Polyester filter bags show good chemical compatibility with most acids, making them suitable for a wide range of industrial applications.

Tip: Always consider the chemical compatibility and temperature requirements of your process before choosing bag filter media.

Durability and Longevity

Durability and extended service life are key considerations for bag filter media. Nylon filter bags feature superior mesh strength and resist weak acids and alkalies, which contributes to their extended service life. Polyester filter bags also provide good resistance to wear and tear, but their mesh strength is generally lower than nylon. The table below highlights the durability ratings for both materials:

| Property | Nylon | Polyester |

|---|---|---|

| Resistance to weak acids | Superior | Resistant |

| Resistance to strong acids | Attacked | Slow attack |

| Resistance to weak alkalies | Superior | Resistant |

| Resistance to strong alkalies | Resistant | Attacked |

| Mesh strength | Stronger | Weaker |

| Max recommendable temperature | 350°F | 250°F |

Nylon filter bags help minimize operational costs by extending the time between filter changes. Their long lifespan and chemical compatibility make them a preferred choice for many industrial processes. Proper maintenance of bag filter media is essential to avoid system damage and inefficiencies. Polyester filter bags also offer durability, but repeated cleaning may affect their efficiency and effectiveness.

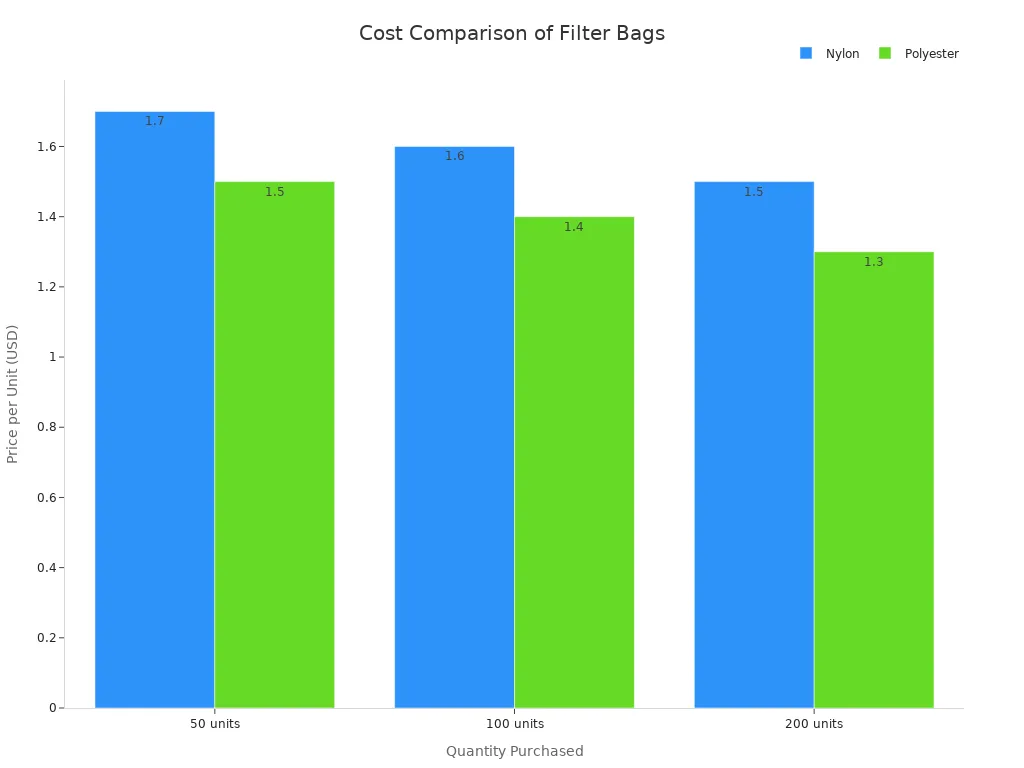

Cost Comparison

Cost is a significant factor when evaluating bag filter media for industrial use. Polyester filter bags generally offer a lower price per unit compared to nylon filter bags, especially when purchased in bulk. The table below shows the price differences for various quantities:

| Type of Filter Bag | Quantity | Price per Unit |

|---|---|---|

| Nylon | 50 | $1.700 |

| Nylon | 100 | $1.600 |

| Nylon | 200 | $1.500 |

| Polyester | 50 | $1.500 |

| Polyester | 100 | $1.400 |

| Polyester | 200 | $1.300 |

Nylon filter bags provide excellent value for money due to their superior performance and durability. They reduce maintenance requirements and help minimize operational costs. Polyester filter bags offer affordability and efficiency, making them a popular choice for many industries. Both types of bag filter media deliver optimal filtration results, but the final decision often depends on budget, application, and desired extended service life.

Note: Selecting the right bag filter media involves balancing filtration efficiency, chemical compatibility, durability, and cost to achieve the best outcome for your filtration system.

Application Suitability and Dust Collector Filter Bag Use

Best Uses for Nylon Filter Bags

Nylon filter bags serve many industries due to their strength and versatility. Companies use bag filter media made from nylon in water filtration, air filtration, and industrial filtration. The food and beverage sector relies on nylon filter bags for compliance and safety. The following table shows common applications:

| Application Type | Description |

|---|---|

| Water Filtration | Removes impurities from water sources. |

| Air Filtration | Traps particles in air cleaning systems. |

| Industrial Filtration | Separates solids from liquids in manufacturing. |

| Food and Beverage Filtration | Ensures safety in food processing and beverage production. |

Industries such as pharmaceuticals, biotechnology, and chemical processing prefer nylon bag filter media for tasks like sterilization and clarification. Nylon filter bags also excel in dust collector filter bag systems, where their abrasion resistance and mechanical strength reduce replacement frequency. Their chemical compatibility with alkalies and organic chemicals makes them reliable in challenging environments.

Nylon filter bags offer high filtration efficiency, durability, and easy maintenance. They remove bacteria and microorganisms, which is essential for food safety.

Best Uses for Polyester Filter Bags

Polyester filter bags provide effective filtration in chemical, pharmaceutical, and petrochemical industries. Companies use this bag filter media for filtering aggressive chemicals, solvents, and oils. The table below highlights typical applications:

| Industry | Application Description |

|---|---|

| Chemical Industry | Filtration of chemicals and solvents. |

| Pharmaceutical Industry | Filtering liquids for product purity. |

| Food and Beverage Industry | Filtration of oils and syrups. |

| Water Treatment | Wastewater filtration to remove contaminants. |

| Petrochemical Industry | Filtering petroleum products and oils. |

Polyester bag filter media performs well in dry environments and provides UV resistance. It suits automotive, aerospace, and wastewater treatment applications. Polyester filter bags handle dry particles and dust efficiently, making them a popular choice for many dust collection systems.

Choosing the Right Filter Bag

Selecting the right bag filter media depends on several factors. Users should consider filtration needs, environmental conditions, and maintenance requirements. The table below compares nylon and polyester characteristics:

| Factor | Nylon Characteristics | Polyester Characteristics |

|---|---|---|

| Filtration Needs | Handles hard or sharp particles | Handles dry particles and dust well |

| Environmental Conditions | Superior durability, moderate chemical exposure | Good moisture protection, UV resistance |

| Maintenance and Costs | May require special care | Lasts longer with simple cleaning |

Selecting the right bag filter media ensures optimal performance and cost savings. Nylon filter bags suit demanding environments and critical processes. Polyester filter bags work best for general filtration and dust collection. Companies should match bag filter media to their specific application and environment for the best results.

Tip: Always evaluate process requirements and environmental conditions before selecting the right bag filter media.

Nylon and polyester filter bags differ in material, durability, and filtration efficiency. Nylon suits viscous fluids and meets FDA standards for food safety. Polyester works well for general liquid filtration and dry environments. Filtration experts recommend considering these criteria:

| Criteria | Description |

|---|---|

| Particle Characteristics | Size and type of particles to be removed |

| Process Conditions | Flow rate, pressure, and temperature |

| Filter Media Types | Material compatibility with application |

| Filter Housing | Suitability for specific system requirements |

Selecting the right filter bag means evaluating application needs, environment, and budget. Product quality and regulatory compliance ensure safe and effective filtration.

FAQ

What is the main difference between nylon and polyester filter bags?

Nylon filter bags use monofilament mesh for strength and durability. Polyester filter bags use woven or felted fibers for flexibility and fine particle filtration. Each material suits different filtration needs.

Can nylon filter bags be reused?

Yes. Nylon filter bags offer reusability because of their strong mesh and easy cleaning. Many industries choose nylon for cost savings and long-term use.

Are polyester filter bags safe for food and beverage applications?

Polyester filter bags can be used in food and beverage processing. Users should check for FDA compliance before selecting a specific product for these applications.

Which filter bag works best for high temperatures?

Polyester filter bags perform well in high-temperature environments. They withstand continuous heat up to 250°F. Nylon filter bags also resist heat but suit moderate temperature ranges.

How do I choose the right filter bag for my application?

Tip: Consider the type of liquid, required filtration level, chemical compatibility, and temperature. Review product specifications and consult with filtration experts for the best results.

Post time: Dec-05-2025