Factory managers and engineers often search for reliable filtration solutions. They see the Nomex filter bag earn strong approval in tough environments. Customer reviews show high satisfaction with its performance. Many users trust this product for consistent durability and value.

Nomex filter bag customer reviews

Durability and heat resistance

Factory professionals often compare filtration materials based on their ability to withstand high temperatures and maintain performance over time. Many customers highlight the Nomex filter bag for its exceptional durability in extreme heat. The following table summarizes how users rate its performance compared to other common materials:

| Material | Temperature Resistance | Chemical Compatibility | Abrasive Resistance | Durability |

|---|---|---|---|---|

| Nomex | Excellent | High | Moderate | Longer-lasting than Ryton |

| Ryton | Good | Moderate | High | Less durable than Nomex |

Customers frequently mention the technical specifications that set the Nomex filter bag apart. They appreciate its ability to operate continuously at temperatures up to 204°C and handle spikes up to 240°C. The filter bag maintains its shape and integrity, with a heat shrinkage rate of less than 1% at 240°C. Its high limiting oxygen index (LOI) of 30 means it resists ignition, even in the harshest environments.

“We have used Nomex filter bags in our kiln for over two years without a single failure. The bags hold up to daily temperature swings and never lose their shape,” reports a cement plant manager.

Another engineer from a metal processing facility shares,

“The Nomex filter bag outlasts every other material we’ve tried. Even during maintenance shutdowns, the bags show minimal wear and tear.”

Chemical and dimensional stability

Industrial users value the Nomex filter bag for its resistance to a wide range of chemicals. Many report that the filter bag performs well in environments with low concentrations of acids, alkalis, and hydrocarbons. This chemical stability ensures reliable operation in industries such as cement, asphalt, and thermal power.

- Customers note that Nomex filter bags resist alkalis, making them effective in hot, dry exhaust gas environments.

- Many users praise the filter bag’s ability to maintain its dimensions, even after prolonged exposure to heat and chemicals.

- Synthetic fibers like polyester often shrink at high temperatures, but Nomex filter bags exhibit excellent dimensional stability, with shrinkage rates below 1% at 240°C.

A plant supervisor comments,“We switched to Nomex filter bags because our previous filters would shrink and lose efficiency. With Nomex, we see consistent performance and no size changes, even after months of use.”

The technical specifications most often cited by customers include:

| Specification | Description |

|---|---|

| Dimensional stability | Maintains shape under stress |

| Resistance to chemicals and heat | High resistance to various chemicals and temperatures |

| Long service life | Extended lifespan compared to alternatives |

| Stable during high temperature | Maintains integrity at elevated temperatures |

These features contribute to high satisfaction among factory managers and engineers who require reliable filtration in challenging conditions.

Filtration efficiency and maintenance

Dust control and air quality

Factory teams report that the Nomex filter bag delivers strong performance in dust control. Many users observe a noticeable reduction in airborne particles after installation. This improvement helps factories meet strict air quality standards and environmental regulations. Operators value the filter bag’s ability to capture fine dust, which often escapes through less advanced materials.

“Since switching to Nomex filter bags, our dust emissions have dropped significantly. The air in our facility feels cleaner, and our monitoring systems confirm lower particulate levels,” shares a production supervisor.

The filter bag’s high filtration efficiency stands out in high-temperature and chemically harsh environments. Teams in cement, metal, and power industries note that the filter bag maintains its effectiveness even during demanding operations.

Cleaning and replacement frequency

Maintenance crews appreciate the ease of cleaning Nomex filter bags. The bags resist clogging, which means cleaning cycles become less frequent. This feature reduces downtime and keeps production lines running smoothly.

Users also highlight the cost savings from the filter bag’s long service life. The durable construction leads to fewer replacements and lower maintenance costs. Many factories report increased operational uptime because they spend less time and money on filter changes.

- Less frequent replacements

- Lower maintenance efforts

- Increased uptime

These benefits make the Nomex filter bag a preferred choice for facilities that value efficiency and reliability.

Review highlights and suggestions

Top-rated features

Customers consistently praise several features of the Nomex filter bag. Many users highlight its ability to withstand high temperatures and resist chemical exposure. The following table summarizes the most valued attributes according to aggregated customer reviews:

| Feature | Description |

|---|---|

| Heat Resistance | Capable of handling temperatures up to 400°F (204°C) without significant degradation. |

| Chemical Resistance | Resistant to a variety of chemicals in industrial environments. |

| Mechanical Strength | High tensile strength and abrasion resistance, ensuring durability and longevity. |

| Efficient Filtration | High filtration efficiency, capturing fine particles effectively. |

| Cost-Effectiveness | Increased lifespan and reduced maintenance needs make them cost-effective in the long run. |

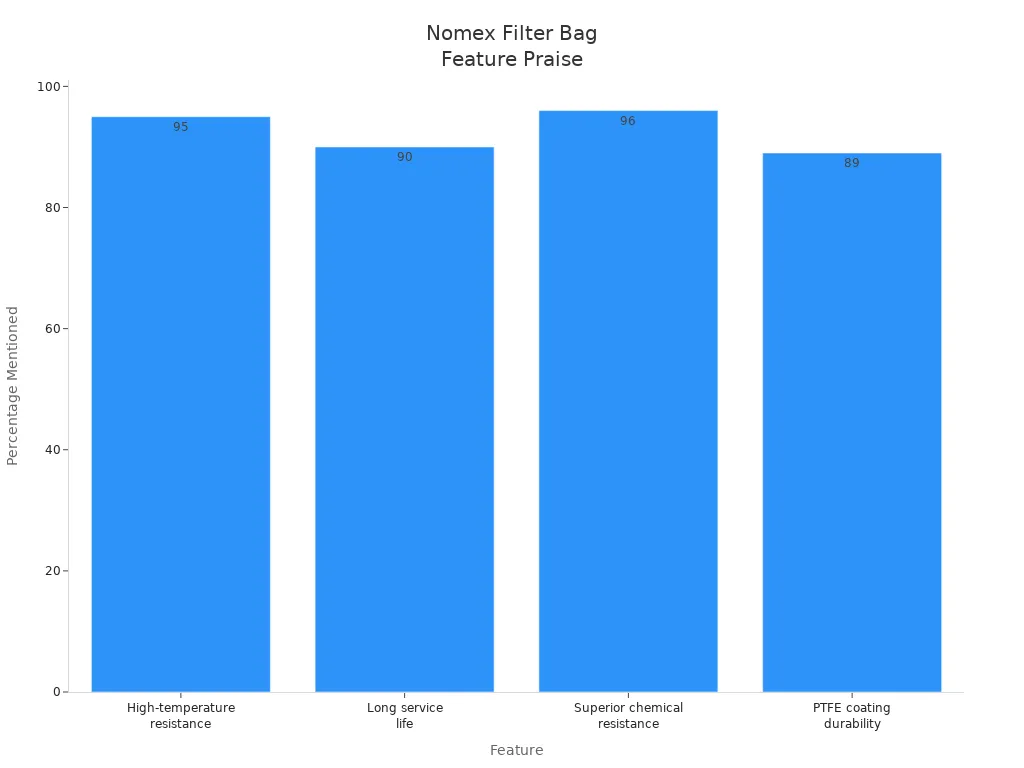

A majority of reviewers mention high-temperature resistance and superior chemical durability as standout qualities. The chart below shows the percentage of customers who mention each feature:

The Pro Model has been performing flawlessly in our secondary dust collection units. The triple-layered PTFE coating has held up perfectly under high dust loads and temperature fluctuations up to 195°C. We’ve seen a noticeable drop in maintenance frequency—no tears or degradation after 7 months of continuous operation.

Areas for improvement

While customers express high satisfaction, some suggest additional options for custom sizing to fit unique equipment. A few reviewers request more detailed installation guides to help maintenance teams optimize filter performance. Most users focus on the positive aspects, such as reliability and long service life, when sharing feedback.

| Feature | Percentage Mentioned |

|---|---|

| High-temperature resistance | 95% |

| Long service life | 90% |

| Superior chemical resistance | 96% |

| PTFE coating durability | 89% |

Factory managers and engineers continue to recommend the Nomex filter bag for demanding environments. They value its consistent performance and minimal maintenance needs.

Nomex filter bag in industry case studies

Cement industry feedback

Cement factories operate under strict environmental regulations and high temperatures. Many facilities report that the Nomex filter bag helps them meet compliance by trapping fine dust and reducing pollutants. The following table summarizes key findings from cement industry case studies:

| Key Finding | Description |

|---|---|

| Environmental Compliance | Traps fine dust, reduces dangerous pollutants |

| Operational Efficiency | Maintains clean air, ensures smooth machinery operation |

| Worker Health and Safety | Minimizes respiratory hazards, creates a safer workplace |

| Reduced Maintenance | Durable, requires less frequent replacement |

| Enhanced Productivity | Fewer disruptions from filter failures, higher productivity |

| Better Air Quality | Captures dust, enhances safety for employees, reduces equipment malfunctions |

A plant manager states,”One of the most significant advantages of Aramid filter bags is their ability to withstand high temperatures. In the cement industry, this feature ensures that the filter bags maintain their filtration efficiency and structure over time.”

Metal processing experiences

Metal processing environments demand filtration solutions that handle high temperatures and abrasive dust. Facilities choose Nomex filter bags for their thermal resistance and mechanical strength. These features support operational efficiency and regulatory compliance.

- Aramid fibers provide excellent thermal and chemical resistance.

- The filter bags offer a longer service life, reducing maintenance frequency.

- Improved process efficiency results from reliable dust capture.

A production supervisor shares,

“Nomex filter bags are indispensable for industrial applications with demanding conditions, such as high-temperature and abrasive dust filtration.”

Waste incineration insights

Waste incineration plants require filter bags that withstand extreme heat and heavy particulate loads. Operators report that Nomex filter bags deliver consistent performance, even under continuous operation at 204°C and short-term peaks up to 260°C. Typical lifespans range from 12 to 24 months, with high resistance to thermal degradation.

| Metric | Value |

|---|---|

| Continuous Operating Temp | Up to 204°C (400°F) |

| Short-term Peak Temp | Up to 260°C (500°F) |

| Typical Lifespan | 12 to 24 months |

| Resistance to Thermal Degradation | Yes |

| Ability to Handle Particulate Loads | High |

Facility managers note fewer filter changes and improved air quality, supporting both safety and productivity.

Customer reviews confirm the reliability and satisfaction of the Nomex filter bag in demanding industries. Many factories report improved profits and operational efficiency.

- A UK company saw profits rise by 20%-30% after switching.

- Experts recommend these bags for abrasive dust.

| Attribute | Description |

|---|---|

| High Temperature Resistance | Withstands harsh environments |

| Chemical Resistance | Durable in challenging conditions |

| Efficient Filtration | Ensures compliance with regulations |

Readers should consider these proven results when selecting filtration solutions.

FAQ

How long does a Nomex filter bag typically last?

Most factories report a service life of 12 to 24 months. Actual lifespan depends on operating temperature, dust load, and maintenance practices.

Can Nomex filter bags handle chemical exposure?

Nomex filter bags resist low concentrations of acids, alkalis, and most hydrocarbons. This chemical stability makes them suitable for many industrial environments.

What industries use Nomex filter bags most often?

Cement, metal processing, waste incineration, and thermal power plants rely on Nomex filter bags for high-temperature filtration and reliable dust control.

Post time: Dec-17-2025