You have hard decisions when you need good filtration in hot places. Many industries, like cement and power plants, use high-temperature filter bags now. This is because air quality rules are very strict. If your filter bag has trouble with high heat, you may want to try a nomex solution. Nomex is made from aramid fibers. Nomex gives thermal resistance, strength, and flexibility. It is better than many other choices.

Filter Bag Requirements for Extreme Temperatures

Key Criteria for High-Heat Filtration

If you work in cement, iron and steel, or asphalt, you need filters that can handle very hot air. Picking the right filter bag helps your baghouse work well and keeps the air clean. Aramid filter bags are a good choice because they stand up to heat and last longer than most other types. These bags help you filter dust from hot air.

Here are some things to look for:

- Handles high heat for long periods

- Stays strong so you do not replace it often

- Resists chemicals from tough gases and dust

- Keeps its size and shape after lots of use

Aramid filter bags, like NOMEX, fit these needs. They stay strong and keep their shape. You do not have to worry about them breaking or needing extra repairs.

Material Properties and Temperature Ratings

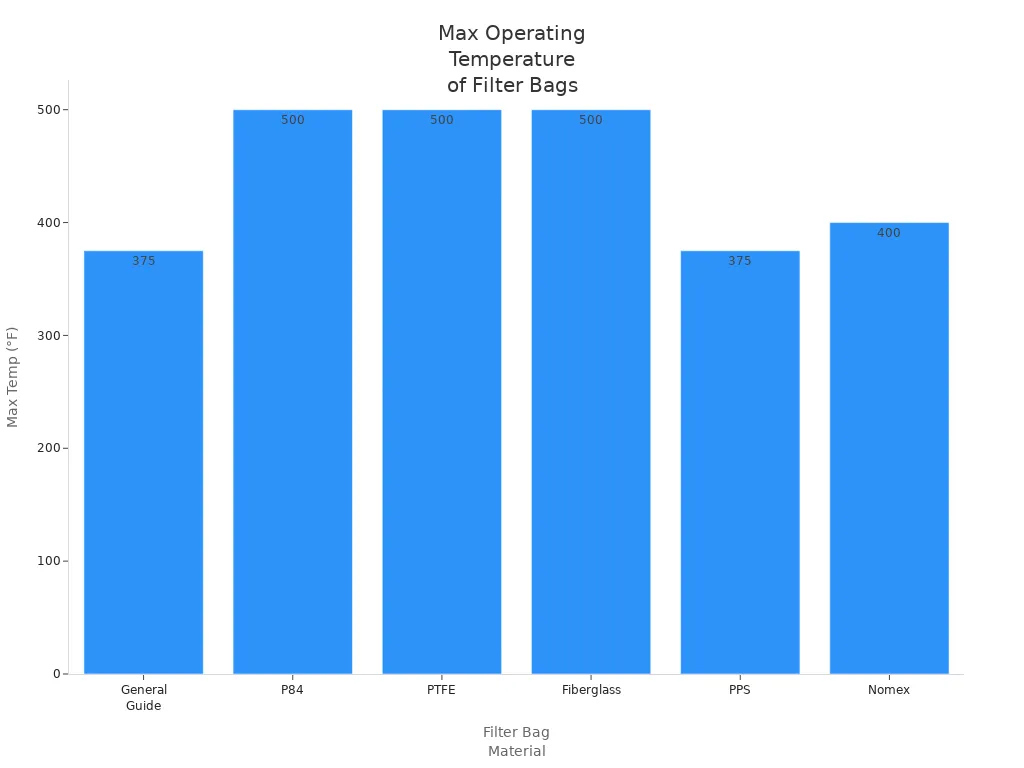

You need to know how much heat each filter bag material can take. Every filter bag has a top temperature it can handle. If you pick the wrong one, your filter may break fast.

Here is a table that shows the highest temperature each filter bag can handle:

| Material | Max Continuous Operating Temperature |

|---|---|

| General Guide | 375°F |

| P84 | 500°F |

| PTFE | 500°F |

| Fiberglass | 500°F |

| PPS | 375°F |

| Nomex | 400°F (spikes to 450°F) |

Aramid filter bags, like NOMEX, work up to 400°F and can handle short spikes up to 450°F. This makes them a smart pick for many hot jobs.

Some filter bags, like PTFE and fiberglass, can take even more heat. But aramid filter bags give you a good mix of heat resistance, strength, and price. They also stand up to many chemicals in industrial gases.

- Polyphenylene Sulfide Felt: 190°C (375°F), great chemical resistance

- Polytetrafluoroethylene Fabric: 260°C (500°F), great chemical resistance

- Fiberglass Fabric: 260°C (500°F), very good chemical resistance

Advanced polymers like PTFE and PVDF are best for chemical resistance and heat. You can use them in the toughest places. But aramid filter bags are often the best deal for most hot jobs.

Common Industry Challenges

Using filter bags in very hot places can be hard. High heat can hurt the filter bag and cause problems.

High heat can make the fabric hard or melt. It can change the size and shape, and cause it to shrink or break.

Too much heat can make the filter bag shrink, melt, or crack. This can cause tears and make the system fail.

High heat also makes chemicals break down the filter bag faster.

If you use aramid filter bags, you lower these risks. These bags are made for tough jobs. They stay strong and keep their shape, even after lots of use in hot places. This means you do not have to replace or fix them as much.

Aramid filter bags, like NOMEX, are strong and resist heat. They last longer and need less fixing. This helps your plant work well and keeps the air clean.

NOMEX Filter Bag Performance

Heat Resistance and Stability

Aramid filter bags can handle very hot air. The NOMEX filter bag works well in places with high heat. You can use it all the time at 204°C. It also stays strong if the temperature jumps to 240°C. You do not need to worry about quick changes in heat.

Tests show NOMEX filter bags stay strong above 200°C. You can check the table to see the results:

| Source | Operating Temperature | Notes |

|---|---|---|

| Nomex heat-resistant dust filter bag | 200 – 220°C | High temperature resistance, acid and alkali resistant |

| Meta-Aramid Nomex Filter Bag | Continuous 200°C | Dry temperature stability |

| Nomex heat-resistant dust filter bag | Up to 220ºC | Very good alkali resistance, suitable for hot dry exhaust |

| Nomex Filter Bags | Stable up to 200°C | Exceptional heat resistance |

You get good filtration even when it gets hotter. The filter bag keeps its shape and does not shrink. Shrinkage stays under 1% at 204°C. Your filter bag lasts longer and keeps working well.

Durability and Safety Features

You want filter bags that last and keep you safe. The NOMEX filter bag has a Limiting Oxygen Index of 30. This means it will not burn in normal air. You lower the chance of fire in your plant.

- The LOI for NOMEX filter bags is 30.

- This means NOMEX does not burn in normal air.

- You get better fire safety and fewer dangers.

NOMEX filter bags also resist chemicals. They stand up to acids and alkalis. You do not need to replace them often. The filter bag keeps fibers from moving, so your liquids stay clean.

- The NOMEX filter bag works up to 204°C.

- Shrinkage is less than 1% at this heat.

You spend less time fixing filter bags. You save money because you buy new ones less often.

Industry Applications

You can use aramid filter bags in many places. The NOMEX filter bag works well in hot and tough jobs. Many industries use them, like chemicals, pharmaceuticals, food and beverage, and water treatment. The table shows why these places pick aramid filter bags:

| Industry | Reason for Adoption |

|---|---|

| Chemicals | High-temperature resistance and durability for handling aggressive chemicals. |

| Pharmaceuticals | Stringent filtration processes required for purity and compliance with regulatory standards. |

| Food & Beverage | Ensures high hygiene standards and product quality in filtering liquids. |

| Water Treatment | Reliable filtration solutions for maintaining water quality and safety. |

You also see aramid filter bags in asphalt, cement, iron & steel, and power plants. These places need strong filters to follow rules and keep workers safe.

- Environmental Compliance: You meet strict rules by trapping dust.

- Operational Efficiency: You help cement plants keep air clean.

- Worker Health and Safety: You lower breathing risks and make work safer.

- Reduced Maintenance: You change filter bags less and save money.

- Enhanced Productivity: You get more work done with fewer filter problems.

- Better Air Quality: You make the air inside your plant cleaner.

You get good performance, safety, and save money with NOMEX aramid filter bags. These filter bags help you reach your goals in tough places.

Comparing NOMEX and Other Aramid Filter Bags

NOMEX vs. Polyester

Polyester is used a lot in baghouse systems. It works fine when the air is not too hot. But polyester cannot handle very high heat like aramid filter bags. When you look at how much heat each can take, you see a big difference:

| Filter Bag Type | Temperature Resistance |

|---|---|

| Polyester | Up to 150°C instantly |

| NOMEX | 200-240°C continuously |

NOMEX works better in places that get very hot. Polyester costs less money. But you might need to buy new polyester bags more often if you use them in hot places. Here is a simple chart for cost and how well they work:

| Filter Bag Type | Cost | Performance Characteristics |

|---|---|---|

| Polyester | Low Cost | Good balance of performance and cost-effectiveness |

| Nomex | Higher Cost | Excellent filtration in high temperatures, longer service life |

NOMEX vs. Polypropylene

Polypropylene is another filter bag people use. It is very good at fighting chemicals, especially acids and bases. But it does not work well when things get hot. NOMEX can handle acids and alkalis and works better when it is hot.

| Material | Chemical Resistance |

|---|---|

| Nomex | Good resistance to acids and alkalis |

| Polypropylene | Exceptional resistance to acids, bases, and many organic solvents |

NOMEX vs. PTFE

PTFE filter bags can take even more heat than aramid filter bags. PTFE can handle up to 250°C (482°F). NOMEX works up to 200°C (392°F). PTFE is best for the hottest jobs. Aramid filter bags give you good heat resistance and cost less.

| Material | Maximum Operating Temperature |

|---|---|

| NOMEX (Aramid) | Up to 200°C (392°F) |

| PTFE | Up to 250°C (482°F) |

Temperature Resistance Comparison

You need to pick the right filter bag for your job. Here is a quick guide:

- NOMEX: 200-240°C, good for most hot jobs.

- Polyester: Up to 150°C, best for warm jobs.

- Polypropylene: Not for hot jobs, but great with chemicals.

- PTFE: Up to 250°C, for the hottest and toughest jobs.

Cost and Maintenance

Aramid filter bags like NOMEX cost more. But they last longer and you do not have to change them as much. Polyester is cheaper, but you might need to replace it more often. PTFE costs the most, but it works in the hottest places. Polypropylene is cheap and great for chemicals, but not for heat.

You should also think about micron retention. NOMEX, polyester, and PTFE can filter from 1 to 200 microns. Polypropylene can filter from 0.1μm to 500μm. This means you have more choices for filtering tiny or big particles.

Tip: To get good filtration and make your filter bag last longer, pick the right bag for your temperature and chemical needs. This helps your system work well.

Choosing the Right Filter Bag

Decision Factors for High-Temperature Use

When you pick a filter bag, you need to think about a few things. Each thing helps you find the best bag for your system. Here are some important points:

- Temperature tolerance: Use aramid if your process is hotter than 200°C.

- Chemical exposure: Pick polypropylene if you use strong acids or bases.

- Flow rate: Bigger bags work better for high flow rates.

- Pressure: Stronger media is needed for high-pressure systems.

- Cost: Think about how much the bag costs and how long it lasts.

“You need to look at temperature resistance, chemical compatibility, and particle size. These things help your filter bag work well in factories.”

Application-Specific Recommendations

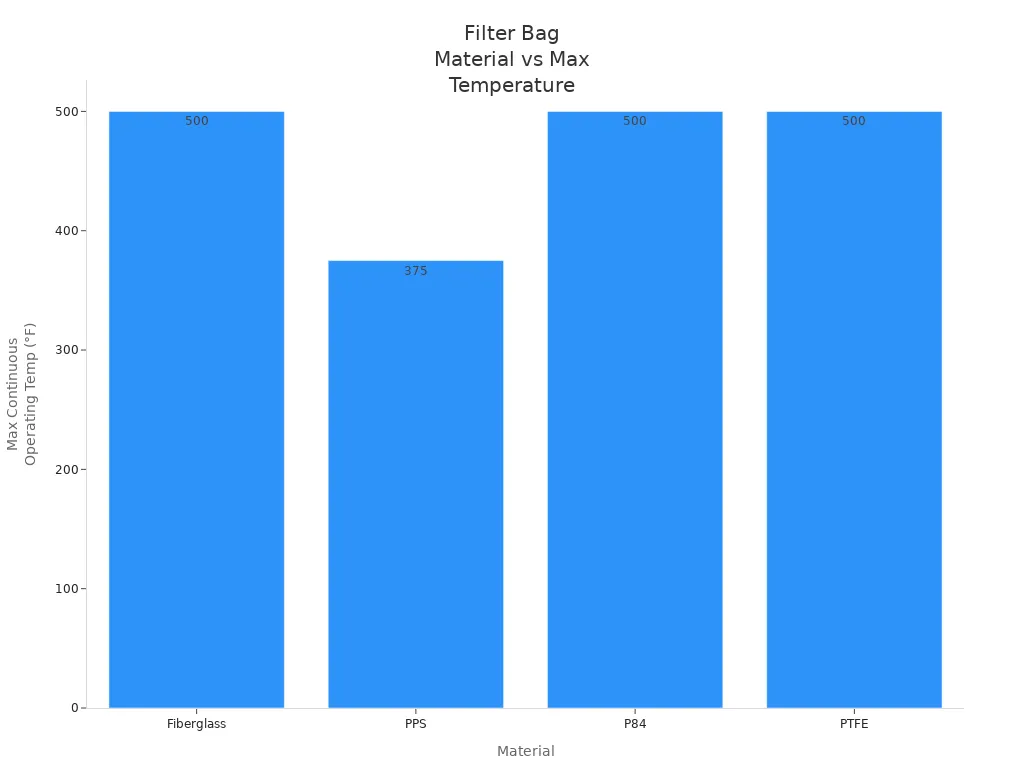

Different jobs need different filter bags. You should match the bag material to your process. The table below shows which materials work best for each job:

| Material | Max Continuous Operating Temperature | Applications |

|---|---|---|

| Fiberglass | 500°F | Energy, chemicals, minerals |

| PPS | 375°F | Asphalt plants, incinerators |

| P84 | 500°F | Waste-to-energy, coal-fired boilers |

| PTFE | 500°F | Steel foundries, carbon black plants |

Every material has a temperature limit. Always check what your process needs before you pick a filter bag.

Maximizing Filter Bag Performance

You can help your filter bag last longer and work better by doing a few things:

- Check the filter housing often for damage or leaks.

- Put the bag in the right way to keep it sealed.

- Change bags on time so your system works well.

- Clean the filter housing to stop dirt from building up.

- Flush the system to get rid of leftover particles.

Custom options let you pick the right size, shape, and surface for your job. Quality checks, like leak tests and making sure the bag fits, help keep your system safe and working well.

NOMEX filter bags protect well in very hot places. They help your system work better and keep people safe. You also save money when you use NOMEX. Many factories have noticed these changes:

- Filter costs can drop by 22% each year.

- Filtration works 15% better than before.

- Maintenance costs go down by 20%.

- Work areas are safer with less fire or dust danger.

| Benefit | Description |

|---|---|

| High-Temperature Resistance | Works in hot places and does not stop working |

| Chemical Resistance | Does not get damaged by acids or alkalis |

| Durability and Longevity | Lasts a long time and needs fewer replacements |

| Efficient Filtration | Catches tiny dust to make air cleaner |

| Cost-Effectiveness | Helps you save money over many years |

Check your filter bags to see how they work. If you want better results, you can try NOMEX. If you need more help, contact us today.

FAQ

What makes NOMEX filter bags good for high temperatures?

NOMEX filter bags use aramid fibers. These fibers resist heat up to 204°C. You can use them in places where other bags might melt or shrink.

Can you use NOMEX filter bags with chemicals?

Yes, you can. NOMEX filter bags resist many acids and alkalis. You get strong performance in chemical plants and other tough environments.

How often should you replace a NOMEX filter bag?

You should check your filter bags often. NOMEX bags last longer than many others. Replace them when you see damage or a drop in performance.

What industries use NOMEX filter bags the most?

You find NOMEX filter bags in cement, asphalt, iron and steel, and power plants. These places need strong filters for hot and dusty air.

Do NOMEX filter bags come in different sizes?

Yes! You can choose from many sizes and micron ratings. This helps you match the right bag to your system and needs.

Post time: Nov-20-2025