Engineers must choose precision filtration products carefully for high-purity fluid systems. Common contaminants include:

- Water

- Sludge

- Gum

- Varnish

- Hard particles

- Chemical degradation by-products

Selecting the right filter means understanding fluid properties, evaluating filter performance, and considering micron rating, filtration efficiency, resistance, and failure modes.

Application Needs & Contaminant Identification

Fluid Type & Properties

Selecting the right precision filtration products starts with understanding the fluid in the system. Fluids in high-purity applications include water, solvents, gases, and biological solutions. Each fluid type has unique properties that affect filtration needs. For example, membrane filters made from PES, PVDF, Nylon, or PTFE are designed for removing microbes and fine particles. Capsule filters offer compact, pre-sterilized options for laboratory and small-scale production use.

| Filter Type | Material Used | Application Description |

|---|---|---|

| Membrane Filters | PES, PVDF, Nylon, PTFE | Microbial and fine particle removal in high precision systems |

| Capsule Filters | Various | Compact, pre-sterilized for labs and small-scale production |

Contaminant Types & Removal Goals

Identifying contaminants is essential for maintaining purity. Common contaminants include particles, microbes, organic compounds, and chemical residues. Engineers use several methods to detect and quantify these impurities:

- Liquid chromatography helps identify and measure contaminants, especially in pharmaceuticals.

- Preparing mobile phases freshly and filtering them reduces contamination risks.

- Regular rinsing of solvent lines and glassware prevents microbial growth.

- Monitoring for environmental contaminants, such as phthalates, protects reagent stability.

Advanced tools like particle counters and TOC analyzers detect even trace levels of impurities. Serial filtration using membrane filters and water purification processes, such as reverse osmosis, further enhance contaminant removal.

Purity Standards & System Constraints

Industry-specific purity standards guide the selection of filtration products. Semiconductor manufacturing demands ultra-high purity gases to prevent wafer contamination. Pharmaceutical production relies on high purity nitrogen to protect product integrity. Food packaging uses industrial grade nitrogen to preserve quality.

| Industry | Purity Standard | Specific Requirements |

|---|---|---|

| Semiconductor | Ultra High Purity (UHP) | Ultra pure gases; impurities can destroy wafer batches |

| Food & Beverage | High Purity Nitrogen | Preserves quality and extends shelf life |

| Pharmaceuticals | UHP Gases | Prevents impurities that compromise product integrity |

System constraints also affect filter selection. Temperature, pressure, and flow rate determine which filters will perform best. Space availability and piping design influence filter housing choices. Engineers must consider pressure drops and differential pressure, especially as filters clog during continuous operation.

Tip: Matching filter rating and media amount to system flow and pressure ensures reliable performance and minimizes downtime.

Precision Filtration Products: Selection Criteria

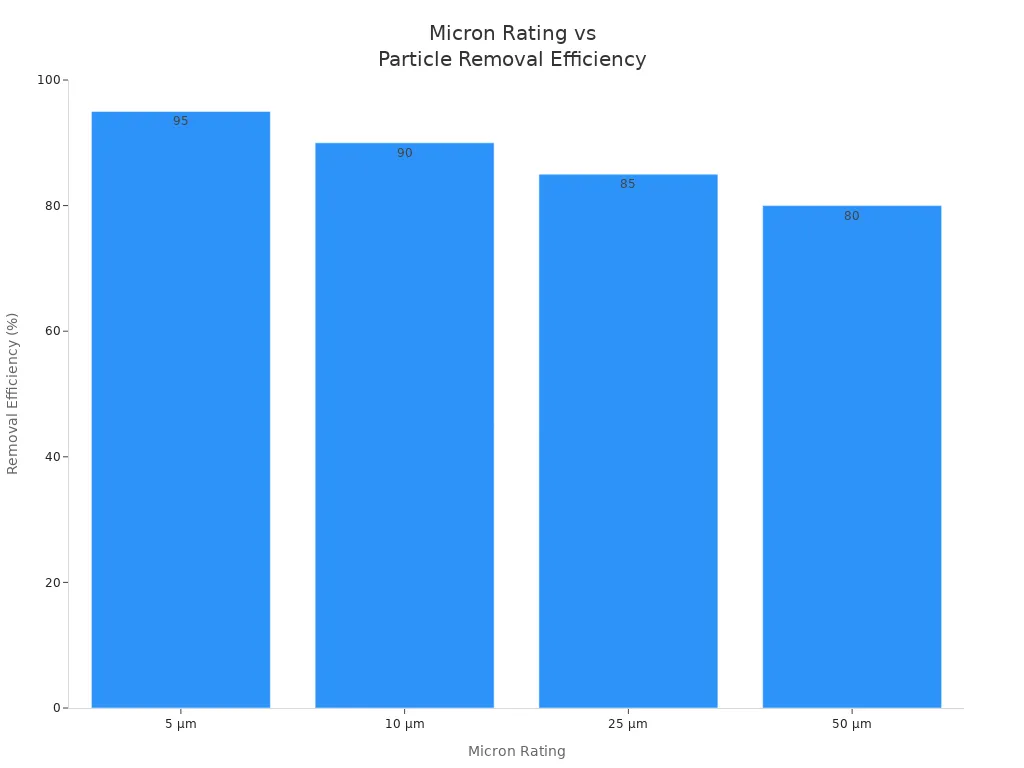

Micron Rating & Filtration Precision

Selecting the correct micron rating is essential for achieving the desired purity in high-purity applications. Micron rating refers to the size of particles a filter can remove. Absolute micron ratings guarantee a specific efficiency, while nominal ratings offer a range that can vary by manufacturer. The following table compares absolute and nominal micron ratings:

| Micron Rating Type | Efficiency | Testing Standard |

|---|---|---|

| Absolute | ≥98.7% | ISO 16889 |

| Nominal | 50-95% | Variable |

Absolute filters provide high reliability, with efficiencies such as βx = 75 (98.7%), βx = 200 (99.5%), and βx = 1000 (99.9%). Nominal filters remove 50% to 95% of particles at the stated size, but this can differ between brands. The following table shows how different micron ratings affect particle removal efficiency:

| Micron Rating | Particle Removal Efficiency |

|---|---|

| 5 µm | >95% |

| 10 µm | >90% |

| 25 µm | >85% |

| 50 µm | >80% |

Precision filtration products with lower micron ratings capture smaller particles but may reduce flow rate. Engineers must balance filtration precision with system requirements.

Tip: Always match the micron rating to the smallest contaminant that must be removed for the application.

Material Compatibility

Filter material compatibility ensures long-term performance and prevents system failures. Incompatible materials can degrade, causing leaks or contamination. Chemical compatibility charts help engineers select the right filter for each fluid. The table below lists common filter materials and their applications:

| Filter Material | Application | Compatibility |

|---|---|---|

| ZTEC™ E | Aqueous chemicals | Critical particle control down to 0.03 micron |

| TefTEC™ | Aggressive chemicals | Hydrophobic PTFE membrane |

| Citadel® | Critical applications | All-fluoropolymer filter |

| QMA | Ultrapure applications | High-efficiency, hydrophilic membrane |

- PTFE works well with aggressive chemicals like acetone and DMSO.

- PVDF suits aqueous and some organic solvents.

- Nylon handles alcohols and DMSO.

- PES is best for non-aggressive aqueous solutions and biological fluids.

Choosing the correct material for precision filtration products prevents membrane failure and maintains system integrity.

Filter Resistance & Flow Rate

Filter resistance directly affects system flow rate and energy consumption. High resistance increases pressure drop, requiring more energy to maintain flow. The following table summarizes the impact of filter resistance:

| Flow Rate Impact | Description |

|---|---|

| Pressure Drop | Increases with flow rate, requiring more energy to maintain flow. |

| Energy Consumption | Higher flow rates lead to increased energy costs due to resistance. |

| Filter Media Lifespan | High flow rates clog media faster, reducing lifespan. |

Engineers should monitor pressure drop to assess filter lifespan. New filters typically show an initial pressure drop of 0.5 to 1.5 inches of water gauge. When the pressure drop reaches 2.0 to 3.0 inches, the filter nears the end of its useful life. Exceeding these limits can cause system malfunctions and reduce air quality.

Note: Balancing flow rate and filter resistance extends filter life and reduces maintenance costs.

Failure Modes & Reliability

Understanding failure modes helps engineers select reliable precision filtration products. Corrosive fluids can damage filter elements, leading to leaks and contamination. Corrosion often appears as red stains in iron or blue-green stains in copper, signaling material failure. Coated filters can improve corrosion resistance by up to 50 times, depending on the application and coating type.

Reliability data from semiconductor fabrication shows that advanced filtration, such as ULPA filters targeting 0.12 µm particles, can reduce defects by 40%. The table below highlights filtration performance in critical environments:

| Filtration Type | MPPS Target | Defect Reduction |

|---|---|---|

| HEPA | 0.3 µm | N/A |

| ULPA | 0.12 µm | 40% |

Selecting precision filtration products with proven reliability ensures consistent performance and protects sensitive processes.

Engineers should always consider the interaction between micron rating, material compatibility, and filter resistance. Balancing these factors leads to optimal filtration performance and system longevity.

Performance Verification & Common Mistakes

Testing & Certification

Verifying filter performance ensures reliable operation in high-purity systems. Engineers use several standard testing protocols to evaluate filters. These tests measure efficiency, safety, and durability under real-world conditions.

| Testing Method | Description |

|---|---|

| Dynamic performance test method | Measures filtration efficiency using passability tests and light scattering particle counting. |

| Biosafety verification | Uses the Pseudomonas aeruginosa challenge test to confirm resistance to high bacterial loads. |

| Extreme working condition simulation | Tests filters at low temperatures to check performance in cold environments and reduce failure rates. |

| Integration of intelligent testing systems | Employs advanced equipment for better detection and remote monitoring. |

| Multi-dimensional evaluation system | Assesses various quality indicators through a comprehensive evaluation model. |

Certifications also play a key role in quality assurance. The most recognized certifications include:

| Certification | Description |

|---|---|

| ISO 9001:2015 | Confirms quality management and compliance with industry standards. |

| AS9100 | Ensures quality and traceability for aerospace, marine, and defense applications. |

Regular integrity testing, such as bubble point testing, helps maintain compliance and ensures filters work as intended. Without proper verification, systems may experience reduced efficiency, increased stress on components, or even complete failure.

Avoiding Selection Errors

Engineers sometimes make mistakes when choosing filters. The most frequent errors include:

| Mistake | Description |

|---|---|

| Overlooking Fluid Characteristics | Ignoring fluid properties can cause poor performance. Always check viscosity, temperature, and chemical compatibility. |

| Ignoring Maintenance Needs | Skipping regular maintenance shortens filter life and reduces effectiveness. |

Selection errors often lead to higher maintenance costs and lower system performance. Frequent filter changes, unplanned downtime, and equipment damage can result. Poor-quality filters allow contaminants to pass through, which increases wear on critical parts and raises repair costs.

Tip: Always match filter selection to system requirements and verify performance through testing and certification.

A systematic approach helps engineers select filters that match application needs and meet purity standards. Testing methods show that environmental conditions affect filter efficiency. Technical resources, such as expert articles and training, improve decision-making. Long-term benefits include enhanced reliability, regulatory compliance, and cost efficiency.

| Benefit | Description |

|---|---|

| Enhanced Reliability | Consistent performance reduces downtime. |

| Regulatory Compliance | Products meet evolving standards. |

| Cost Efficiency | Lower maintenance and energy costs. |

| Innovation Adoption | Early use of new technologies improves efficiency. |

FAQ

What does micron rating mean in filtration?

Micron rating shows the smallest particle size a filter can remove. Lower micron ratings capture finer particles, improving purity in high-purity systems.

How often should engineers replace precision filters?

Engineers should check pressure drop and follow manufacturer guidelines. Most filters need replacement when pressure drop doubles or reaches the recommended limit.

Which filter material works best for aggressive chemicals?

| Chemical Type | Recommended Material |

|---|---|

| Acetone, DMSO | PTFE |

| Strong acids | All-fluoropolymer |

| Alcohols | Nylon |

Post time: Dec-24-2025