Choosing the right filter starts with one question: what do you need to remove? You must first identify the size of the particles in your liquid. With industries releasing millions of pounds of contaminants, effective filtration is crucial. Select a nylon filter bag with a micron rating that matches your target.

Tip: Your filter’s micron rating should be equal to or slightly smaller than the smallest particle you want to capture.

Understanding Key Filtration Concepts

Before you select a filter, you need to understand a few basic ideas. These concepts will help you choose the perfect micron rating for your specific job.

Identifying Your Target Particle Size

The first step is to know the size of the contaminants you want to remove. Filtration measurements use a unit called a micron, which is one-millionth of a meter. For perspective, a human hair is about 50 to 100 microns thick. You can use professional methods like laser diffraction or image analysis to find the exact size of your particles.

Common contaminants have a wide range of sizes. Knowing these can help you estimate your needs.

| Contaminant | Particle Size (microns) |

|---|---|

| Bacteria | 0.3 – 60 |

| Silt (very fine) | 4 – 8 |

| Fine Sand | 125 |

| Coarse Sand | 500 |

Defining Your Desired Fluid Clarity

How clean does your liquid need to be? You can measure fluid clarity in a few ways. One method uses Nephelometric Turbidity Units (NTU), which measure how light scatters in a liquid. A lower NTU value means the liquid is clearer.

Another common standard is ISO 4406. This system uses a three-number code to classify the number of particles at >4, >6, and >14 microns. For example, a target rating for hydraulic oil might be ISO 16/14/11.

Nominal vs. Absolute Ratings

Filter ratings are not all the same. You will see two main types: nominal and absolute.

A nominal rating means the filter captures a certain percentage of particles at a specific micron size, usually between 50% and 98%. This rating is less precise. An absolute rating guarantees the filter removes at least 99.9% of particles at or above the stated micron size.

For general-purpose tasks, a nominal-rated nylon filter bag may be sufficient. For high-purity applications where no bypass is allowed, you must choose an absolute-rated filter.

Selecting the Right Nylon Filter Bag Rating

Once you understand the basics, you can connect them to your real-world needs. The right micron rating depends heavily on your specific process and the properties of the liquid you are filtering.

Matching Rating to Your Application

Different industries require different levels of filtration. You should choose a micron rating based on the specific contaminants you need to remove for your application. For example, industrial filters often remove particulates and sediment down to 10 microns from water.

Here are some common examples to guide you:

- Food and Beverage: This industry needs precise filtration. In brewing, a 1-micron filter is often the sweet spot. It removes most yeast without stripping flavor. A filter smaller than 0.5 microns might alter the taste. For very clear liquids, a 0.45-micron filter can provide sterilization.

- Water Treatment: Protecting sensitive equipment is key. For reverse osmosis (RO) systems, a 5-micron filter is a common pre-filtration standard. If your water has a lot of sediment, you might use a 20-micron filter first, followed by 5-micron and 1-micron filters to protect the RO membrane.

- Chemical Processing: Your filter material must be compatible with your fluids. A nylon filter bag works well with many industrial liquids. Nylon offers reliable performance in environments with moderate chemical exposure. However, you should always check its resistance to specific chemicals.

| Chemical Type | Resistance |

|---|---|

| Organic Solvents | Very Good |

| Alkalies | Good |

| Oxidizing Agents | Fair |

| Mineral Acids | Poor |

| Organic Acids | Poor |

Knowing your application’s standard helps you select the correct nylon filter bag. The table below shows how precise some applications can be.

| Application | Micron Rating |

|---|---|

| Dialysis Water Filtration | 0.2 μm |

| Beer Filtration | 0.45 μm |

Factoring in Flow Rate and Viscosity

Your fluid’s properties also affect your filter choice. Flow rate and viscosity are two of the most important factors to consider.

Flow Rate is the speed at which your liquid moves through the filter. There is an inverse relationship between micron rating and flow rate. A smaller micron rating means finer filtration, which can slow down the flow.

- A filter that is too restrictive can impede flow. This may cause unfiltered liquid to bypass the filter.

- A filter with too much flow may not work well. The liquid moves too quickly for the filter to trap contaminants effectively.

The key is to balance flow with filtration efficiency. High-performance filters can maintain optimal flow while capturing smaller particles.

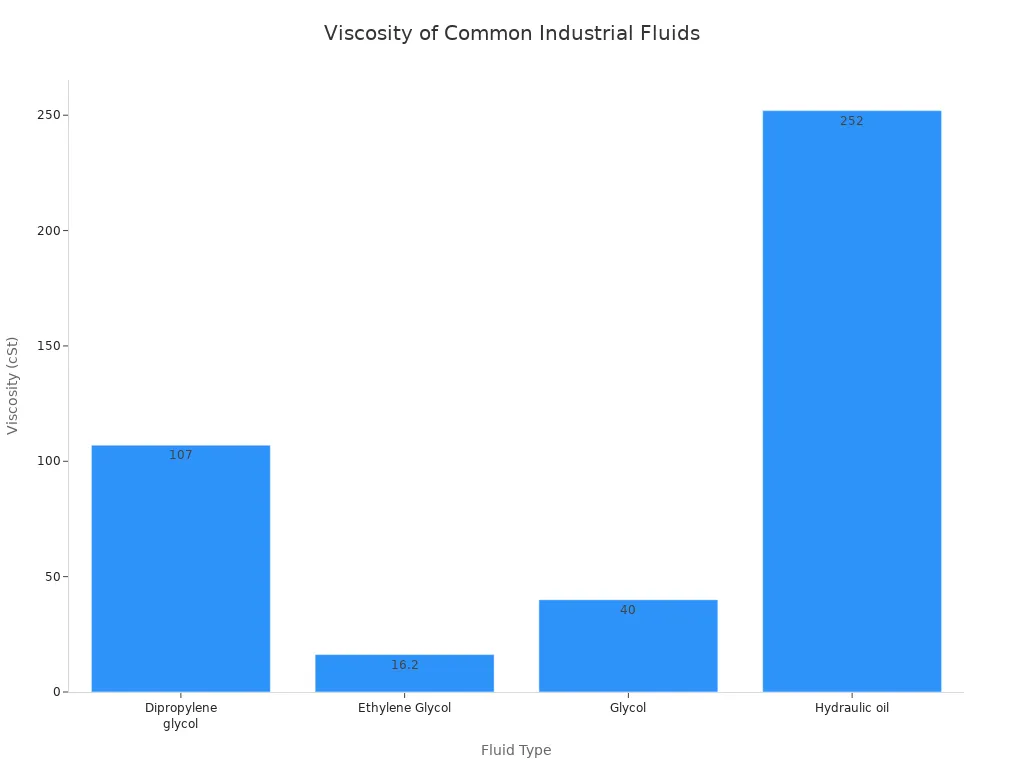

Viscosity is a measure of a fluid’s thickness or resistance to flow. Fluid viscosity is a primary factor that influences the pressure across a filter. An increase in viscosity leads to a higher initial pressure difference. This means thicker liquids require more force to push through a filter.

When filtering high-viscosity liquids like hydraulic oils or glycols, you may need a filter with a larger micron rating or a larger surface area to maintain a good flow rate without creating too much back pressure. The Precision Filtration nylon filter bag is crafted to be particularly effective for filtering high viscous liquids.

| Fluid Type | Viscosity (cSt) | Temperature (°C) |

|---|---|---|

| Ethylene Glycol | 16.2 | 20 |

| Hydraulic oil | 30 – 680 | 20 |

| Glycol | 40 | 20 |

| Dipropylene glycol | 107 | 20 |

Considering these factors helps you choose a filter that not only cleans your liquid but also works efficiently within your system.

Choosing the right filter is a clear process.

- First, identify your target particle size.

- Next, understand the difference between nominal and absolute ratings.

- Finally, select a micron rating for your application, considering fluid properties.

If you are still unsure, contact our specialists for a personalized recommendation on the best nylon filter bag.

FAQ

What happens if I choose the wrong micron rating?

A rating that is too large lets contaminants pass through. A rating that is too small clogs quickly. This reduces your system’s flow rate and efficiency.

Can I reuse a nylon filter bag?

Yes, you can clean and reuse our nylon monofilament bags. This feature makes them a very cost-effective choice for many general filtration tasks.

How do I know when to change my filter bag?

Tip: You should monitor the pressure gauge. A significant pressure increase between the inlet and outlet signals a clogged filter that needs replacement.

Post time: Nov-18-2025