Spring filter housing tackles industrial filtration challenges by delivering faster maintenance, higher water quality, and significant cost savings. Operators experience less downtime and improved health and safety.

“We’ve been using the SS304 Quick Open Bag Filter Housing (Pro Model) since February 2025, and it’s transformed our maintenance workflow. The quick-open hinged lid cuts filter changes from 45 minutes down to 15—huge win for uptime.” ⭐⭐⭐⭐⭐ James Wilkins – Water Treatment Plant Manager

This housing design supports water health standards and ensures reliable performance. The table below shows why industries trust this housing for critical water processes:

| Feature | Benefit |

|---|---|

| Integrated spring mechanism | Holds filter cartridges securely, preventing leaks |

| Continuous pressure | Enhances filtration efficiency |

| Durable materials | Ensures reliable performance under pressure |

| Easy installation/removal | Speeds up maintenance and replacement processes |

| Widely used in industries | Supports efficient operation in filtration systems |

Modern spring filter housing adapts to demanding water applications, protecting water health and maximizing housing efficiency.

Spring Filter Housing for Maintenance and Downtime

Quick Filter Changes

Spring filter housing transforms the way industries handle water filtration by streamlining filter changes. The spring-aided closure mechanism allows operators to access the filter bags quickly, reducing the time needed for each change. Traditional stuck filter housings often require significant effort and time to open, which can lead to delays and frustration. With the spring-assisted design, operators can open the housing in seconds, not minutes, preventing stuck housings and ensuring a smooth workflow.

- The spring-aided closure mechanism provides fast access to consumables, cutting filter bag change time dramatically.

- Quick-open systems require less effort for servicing, making the process more efficient.

- The spring-assisted balance allows for simple operation, even in demanding water filtration environments.

This approach not only prevents stuck filter housings but also minimizes the risk of injury and equipment damage. Operators no longer struggle with stuck housings or excessive eye bolts, which often slow down water system maintenance. Instead, they benefit from a design that prioritizes ease of use and reliability.

Tip: Regularly inspect the spring mechanism to ensure optimal performance and continued prevention of stuck filter housings.

Minimizing Downtime in Filtration

Reducing downtime remains a top priority for any water-intensive industry. Spring filter housing directly addresses this challenge by enabling faster filter changes and preventing stuck housings, which often cause unplanned shutdowns. The impact on productivity and labor requirements is significant.

- The switch to advanced filter designs, such as pleated bag filters, extends filter change-out intervals from every 5 weeks to every 24 months.

- Filter change-out time drops from 12 hours to just 4 hours, minimizing lost production time.

- Unplanned downtime losses, which can reach $20,000 per hour, decrease as maintenance becomes more predictable and efficient.

- Lower pressure drop and reduced filter abrasion issues further contribute to operational stability.

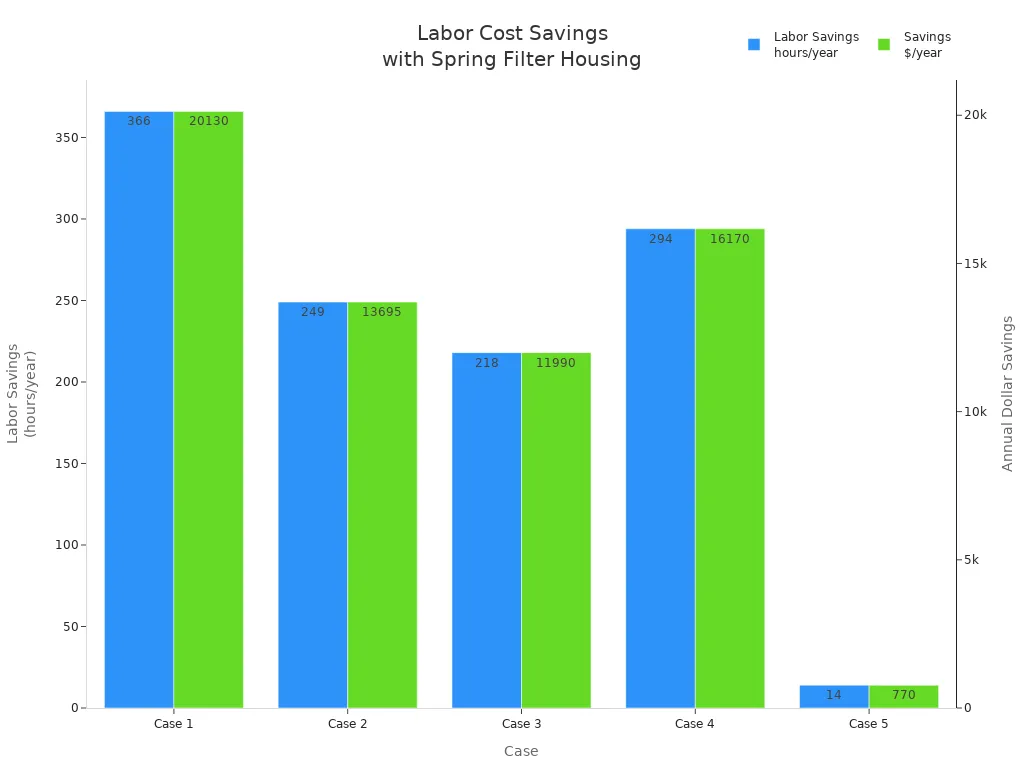

The following table highlights the labor cost savings achieved through the use of spring filter housing in water filtration systems:

| Labor Savings (hours/year) | Savings ($/year) |

|---|---|

| 366 | 20,130 |

| 249 | 13,695 |

| 218 | 11,990 |

| 294 | 16,170 |

| 14 | 770 |

| Total | 62,755 |

| Total Labor Savings | 1,141 hours |

Spring filter housing also enhances overall productivity in water filtration plants:

- The design allows for quick access to filters, enabling easy cleaning or replacement without special tools.

- High-efficiency filtration systems handle higher pressure and flow rates, preventing disruptions in water operations.

- Durable housing construction ensures long-lasting performance, reducing the frequency of maintenance and downtime.

By preventing stuck filter housings and simplifying maintenance, spring filter housing helps industries overcome common challenges in water filtration. This leads to improved water quality, greater operational efficiency, and substantial cost savings.

Filtration Performance, Safety, and Cost

Consistent Water Quality

Spring filter housing delivers reliable filtration for industrial water systems. The design ensures tight sealing, which prevents leaks and maintains high water quality. Operators rely on this housing to remove up to 99% of large particulates, including sediments, dirt, rust, and sand. The auto-flushing feature keeps the filter efficient over extended periods. Durable materials resist corrosion, supporting long-term water protection. Siliphos inclusion prevents scale and corrosion, extending the life of plumbing fixtures and maintaining water quality.

| Feature | Description |

|---|---|

| Sediment Removal | Removes up to 99% of large particulates such as sediments, dirt, rust, sand |

| Auto-Flushing | Advanced feature that helps maintain filter efficiency |

| Durable Materials | Designed to withstand long-term use and prevent corrosion |

| Siliphos Inclusion | Prevents scale and corrosion, extending plumbing fixture life |

Spring filter housing uses a self-adjusting sealing device. This mechanism minimizes fluid leakage and supports positive sealing for various filter types. Operators avoid stuck filter housings, which often compromise water quality and filtration performance.

| Feature | LMO Spring Seal Series | Conventional Filter Housings |

|---|---|---|

| Sealing Mechanism | Self-adjusting sealing device | Standard sealing methods |

| Leakage Prevention | O-ring head and shell seals | Higher risk of leaks |

| Filter Compatibility | Positive sealing for many types | May not support all types |

Operator Safety in Filter Maintenance

Safety remains a top priority in industrial filtration. Spring filter housing features a 3-point balance hold, which stabilizes the cover during maintenance. Operators gain easy access to the filter, reducing the risk of injury. The housing design eliminates the need for excessive eye bolts, which often slow down maintenance and increase the risk of stuck filter housings. The spring-assisted closure mechanism allows operators to open and close the housing with minimal effort.

- Operators handle fewer heavy components, lowering the risk of strain.

- The balance hold keeps the cover secure, preventing accidental drops.

- Easy access to the filter reduces exposure to hazardous water and chemicals.

- The housing supports engine protection systems by maintaining clean water for cooling and lubrication.

Tip: Always check the balance hold and spring mechanism before starting maintenance to ensure safe operation.

Cost-Effective Filtration Solutions

Spring filter housing offers significant cost advantages for industrial water filtration. ASME construction standards guarantee high material quality and controlled welding, which increases durability. Operators benefit from thorough documentation and testing, ensuring housing integrity and long service life.

| Aspect | Description |

|---|---|

| Material Quality | ASME BPE-compliant housings use high-grade stainless steel for corrosion resistance |

| Controlled Welding | Standards require precise welding to limit ferrite in heat-affected areas |

| Documentation & Testing | Mandated for quality assurance and integrity |

| Cost Implication | BPE-compliant housings cost more but deliver longer service life and reliability |

Long-term cost analysis shows that spring filter housing reduces total ownership costs. Operators experience lower maintenance labor, fewer filter changeouts, and less downtime. Filters with higher dirt-holding capacity generate less waste, lowering disposal costs. Reliable filtration prevents production losses and equipment damage, supporting water protection and engine performance.

- Service life extends, reducing replacement frequency.

- Operational burden decreases as filters minimize pressure drop.

- Maintenance labor drops due to easy access and quick filter changes.

- Disposal costs fall with less waste generated.

- Downtime risk lowers, protecting water operations and engine systems.

Spring filter housing stands out as a durable, safe, and cost-effective solution for industrial water filtration. Operators achieve consistent water quality, enhanced safety, and long-term savings.

Versatility in Industrial Applications

Adapting to Different Filters and Fluids

Spring filter housing supports a wide range of filter types and fluids, making it a top choice for industrial water and chemical processes. Operators can select from multiple filter series to match their water or chemical application. The table below shows the compatibility of each housing series with different filter and fluid types:

| Series | Compatible Filters | Compatible Fluids |

|---|---|---|

| FAS and FAC | DOE cartridges in multiple sizes | Water, chemicals, oil/gas |

| FLD | Single cartridge, high flow | Most fluids with various gasket options |

| FO | 1/4″ to 1″ connections | Water, chemicals, desalination, oil/gas, pulp/paper |

| MicroVantage SFH | High purity applications | Ultrapure water, fine chemicals, pharmaceuticals |

Spring filter housing uses high-quality stainless steel to handle aggressive acids, bases, and solvents. This material resists corrosion and supports deionized water in semiconductor and chemical manufacturing. Operators rely on these housings for ultra-high flow rates in water and chemical filtration.

High-flow filter housing meets the needs of water treatment, oil and gas, and semiconductor industries. These systems manage large water volumes with minimal pressure drop. They also ensure compliance with safety and quality standards.

Applications in Aircraft Filtration Systems

Aircraft filtration systems demand advanced performance and reliability. Spring filter housing plays a key role in water and engine protection for aircraft. The aerospace sector uses advanced aircraft filtration to maintain fluid purity and engine safety. Custom aircraft filtration solutions must pass strict tests for fluid compatibility, cryogenic sealing, and ignition resistance.

| Test Name | Description |

|---|---|

| Fluid Compatibility | Ensures filter elements work with water glycols and petroleum oils |

| Cryogenic Sealing | Verifies seal performance at low temperatures |

| Hydraulic Fluid Power | Measures filter efficiency for engine protection |

| Ignition, ASTM-G175 | Confirms ignition resistance for advanced aircraft filtration |

| Separation Efficiency | Assesses particulate removal for water and engine systems |

| High-Flow Testing | Simulates rocket propulsion water flow for advanced aircraft filtration |

Aircraft filtration systems require housing that resists stuck filter housings and supports high-flow water and engine needs. Operators choose spring filter housing for custom aircraft filtration because it delivers consistent water quality and protects critical engine components. Advanced aircraft filtration ensures safety and reliability for every aircraft.

Spring filter housing transforms water filtration for industries that demand reliability, health protection, and cost savings. Operators in water, aircraft, and engine sectors report improved water quality, reduced downtime, and enhanced health standards. The table below highlights how spring filter housing future-proofs water and aircraft filtration systems, supporting engine performance and water health.

| Feature | Benefit |

|---|---|

| Stainless Steel & Thermoplastic | Ensures product purity and system reliability across various industries. |

| Precision Dimensional Control | Enhances compatibility with major OEM filter formats, ensuring adaptability to future needs. |

| Hygienic Internal Surfaces | Reduces contamination risk, crucial for compliance with tightening quality expectations. |

| Pressure-Rated Shells | Provides durability under high pressure, extending the lifespan of the filtration system. |

| Dependable Sealing Systems | Maintains sealing integrity, crucial for operational efficiency and compliance. |

- Regular evaluation of water and aircraft filter housing ensures optimal engine and water system performance.

- Spring filter housing supports water health, aircraft safety, and engine reliability for future-ready operations.

FAQ

What industries benefit most from spring filter housing?

Industries such as water treatment, chemicals, food and beverage, and electronics benefit from spring filter housing due to its efficiency and versatility.

How does spring filter housing improve operator safety?

The spring-aided closure and 3-point balance hold reduce manual effort. Operators handle fewer heavy parts, which lowers the risk of injury during maintenance.

Can spring filter housing handle high flow rates?

Yes. Spring filter housing supports up to 1,000 m³/hr, making it suitable for high-demand applications and large-scale industrial processes.

Post time: Dec-15-2025