Filter Vessel Manufacturers – Mechanical Self Cleaning Filter Vessel – Precision Filtration

Filter Vessel Manufacturers – Mechanical Self Cleaning Filter Vessel – Precision Filtration Detail:

- Design for high viscous and abrasive liquids

- Durable performance with unique bridge actuator system

- Automatically cleaning, filtered fluid automatically exiting.

- Eliminated media disposal costs, no bag, no cartridge.

- Automatic mechanically operation, reduced or eliminated operator intervention.

- Pneumatic driven, no need of electric power, safe, reliable and economic.

- Multi-flow rate available, accommodate a vast range of your application.

- Wide applications, mainly for high viscosity, corrosive liquid, viscosity up to 1000000cp.

Precision Filtration mechanically cleaned filter system designed to handle to filter 20 micron and larger in various industries where high particle contect, viscous and sticky liquid. The system contains a cylindrical filter screen, liquid flow through the screen and dirt retain on the inner surface of the screen (with define filtration opening). Clean disc moving up and down continuously to remove the dirt, and discharge from drain valve at periodical time. Clean disc made by special grade of Teflon disc has a doctoring and wiping edge, both edges are pressed tightly against the screen by mechanical loading. Precision Filtration Self Cleaning Filter Systems Operation Principle Raw liquid enters via the inlet and travels from the inside to the outside of the filter media, contaminants are retained on the inside, clean filtered liquid exits via the outlet. The cleaning disk travels down and then back up by the use of a pneumatic cylinder. The flow pattern concentrates contaminants at the bottom of the filter housing and the concentrated solids are periodically purged. Purging lasts less than one second, releasing only the volume of the collection chamber and avoiding process interruptions. Self Cleaning filters are ideal for continuous flow (and therefore batch) applications. In every case, these filters offer significant advantages over alternative filter designs.

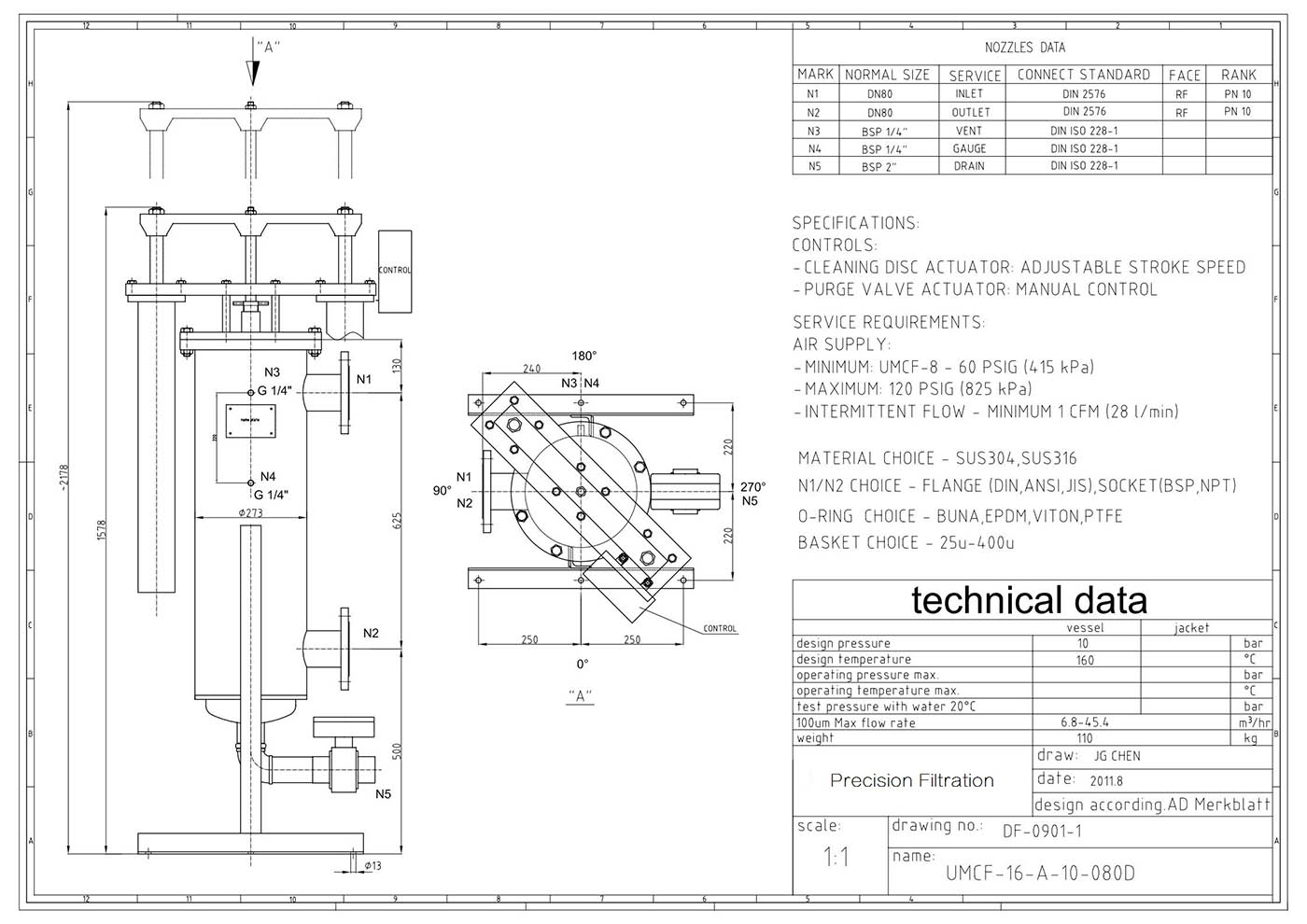

| Specification / Type | UMCF-4 | UMCF-8 | UMCF-16 |

| UMCF Product Picture |  |

|

|

| Filtration Precision | 25um - 400um | 25um - 400um | 25um - 400um |

| Total Volumetric Capacity | 3.5liters | 14.8liters | 41.6liters |

| Purge Chamber Capacity | 119ml | 0.74liters | 6liters |

| Filtration Surface | 722cm2 | 1703cm2 | 3935cm2 |

| 100um (3/hr) | 0.45-6.8m3/hour | 2.27-13.6m3/hour | 6.8-45.4m3/hour |

| Temperature, maximum (℃) | 160 ℃ | 160 ℃ | 160 ℃ |

| Pressure, maximum | 21bar | 10bar(standard) | 10bar(standard) |

| Single Unit Weight | 16kg | 34kg | 97.5kg |

| Service Height | 1556mm | 1760mm | 2591mm |

| Air for Actuator Drive, min. | 4bar@8.5 m3/hr | 4bar@8.5 m3/hr | 5bar@8.5 m3/hr |

| Material of Construction | All Wetted Parts | Type 304 or 316L stainless steel | |

| Filter Element | |||

| Standard Inlet/Outlet | 1 1/2″ BSP socket | 2″ Flange | 3″ Flange |

| Surface Finish | Glass bead blasted |

| Liquid | Viscosity (cps) | UMCF-4 | UMCF-8 | UMCF-16 |

| Max flow rate (m3/hr) | ||||

| water | 1 | 3 | 12 | 45 |

| Glue | 10,000-50,000 | 1 | 4 | 12 |

| Edible Oil | 10-100 | 3 | 12 | 45 |

| Honey | 50-100 | 3 | 12 | 45 |

| Printing Ink | 100-1,000 | 3 | 12 | 45 |

| Ink | 10-100 | 3 | 12 | 45 |

| Coating | 500-1,000 | 3 | 12 | 45 |

| Resin | 5,000-50,000 | 1 | 4 | 12 |

PAINT & COATING

SUGARS

CHEMICAL

THICKENERS

OIL & FATS

DAIRY

FOOD & BEVERAGE

WASTE

PAPER INDUSTRY

WATER

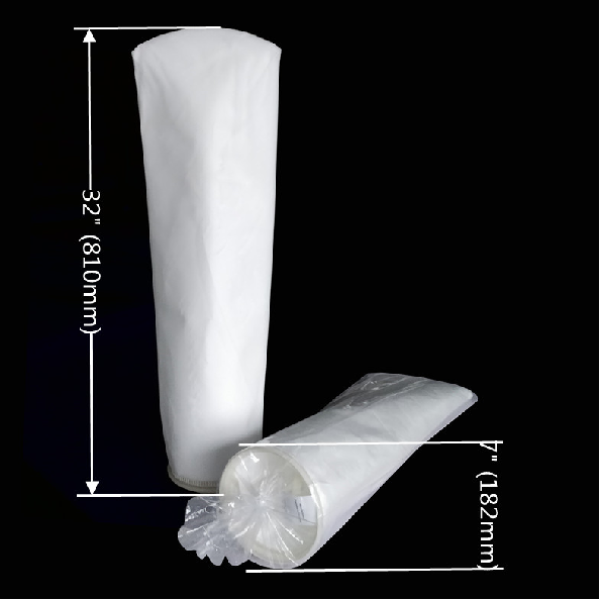

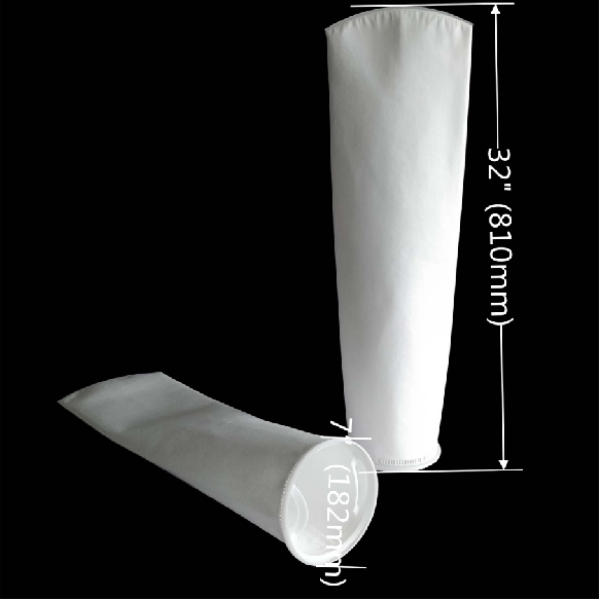

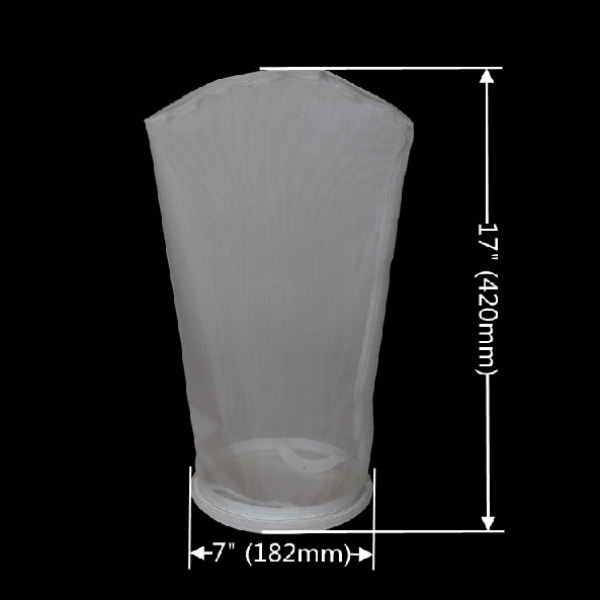

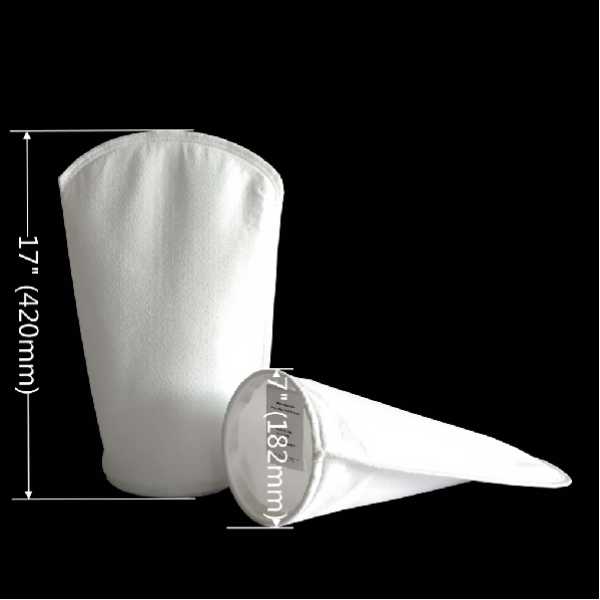

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Filter Vessel Manufacturers – Mechanical Self Cleaning Filter Vessel – Precision Filtration , The product will supply to all over the world, such as: Bahamas, United States, Adelaide, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.