China Wholesale Filter Bag Supplier Suppliers – PTFE Filter Bag – Precision Filtration

China Wholesale Filter Bag Supplier Suppliers – PTFE Filter Bag – Precision Filtration Detail:

Polytetrafluoroethylene (PTFE) synthetic fiber filter bag is a bag made of special materials, in 240 DEG C temperature continuous operation, instant 260 DEG C temperature conditions, ability all pH range of acid-base erosion. PTFE synthetic fiber filter bag self-lubricating excellent, does not absorb moisture, can withstand ultraviolet radiation. But the wear resistance of PTFE fiber filter material generally, so the filter bag frame has more stringent requirements (finish).

PTFE filter bag used for coal-fired boilers, waste incineration, treatment of flue gas in the production of carbon black, titanium dioxide (TiO2) production process, for the first time in the smelting of some metals, refining and chemical production process have also been used.

The main technical parameters of PTFE bag:

Product name A750BSG TF/TF

Fiber 100%PTFE

Fabric 100%PTFE

Square gram weight 750g/m2

Thickness 1.1mm

Density 0.68g/cm3

Air permeability 100L/dm2.min

Longitudinal fracture strength was greater than 450 N/5cm

Horizontal fracture strength greater than 450 N/5cm

Elongation @200N/5cm- longitudinal < 5%

Extension @200N/5cm- horizontal < 5%

Heat shrink 90min, @260degC 3%

Bursting strength > 300 N/cm2

Continuous working temperature 240

Instantaneous working temperature 260

Postprocessing hot styling

|

No. |

Diameter |

Length |

Flow Rate |

Filter Area |

Volume |

|

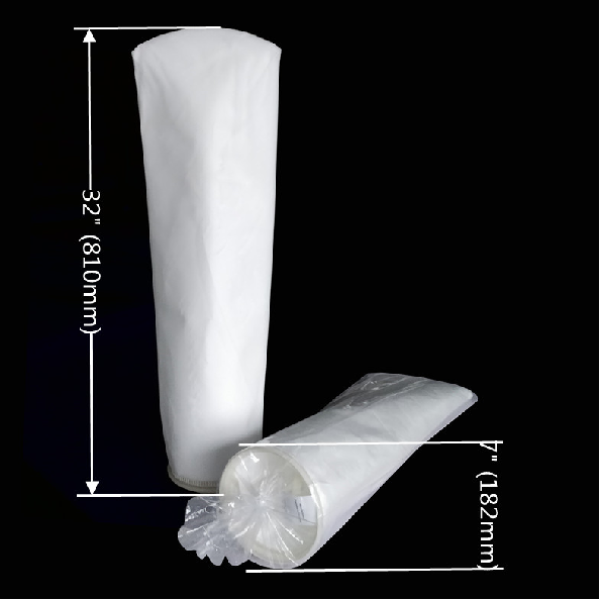

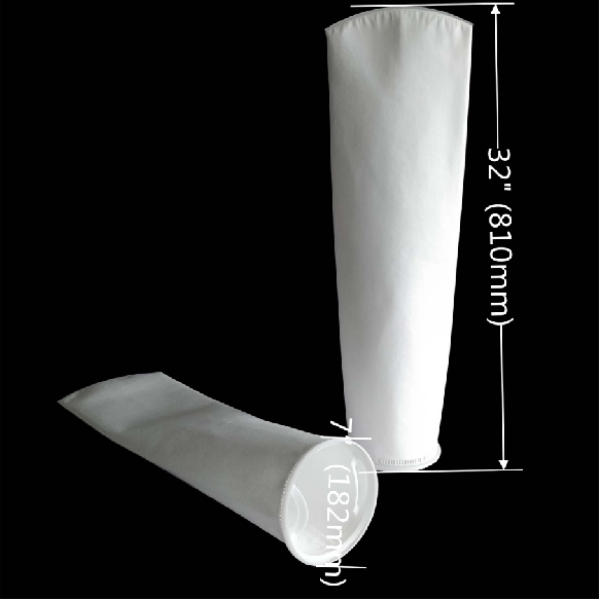

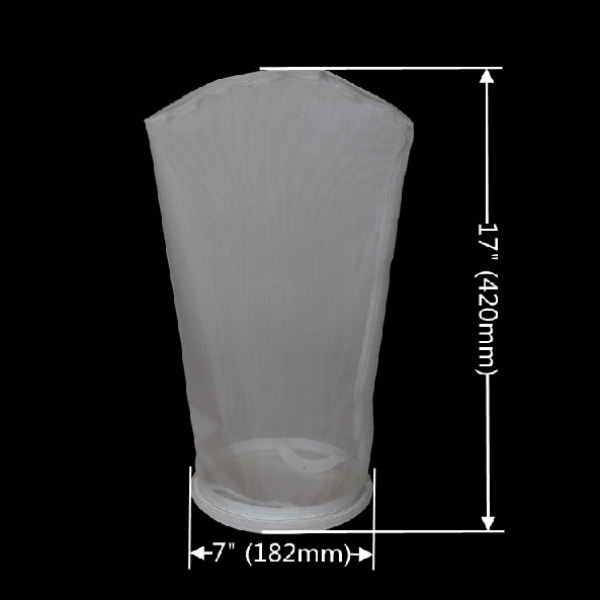

# 01 |

7″ (177.8mm) |

17″ (431.8mm) |

20m3/h |

0.25m2 |

8.0 L |

|

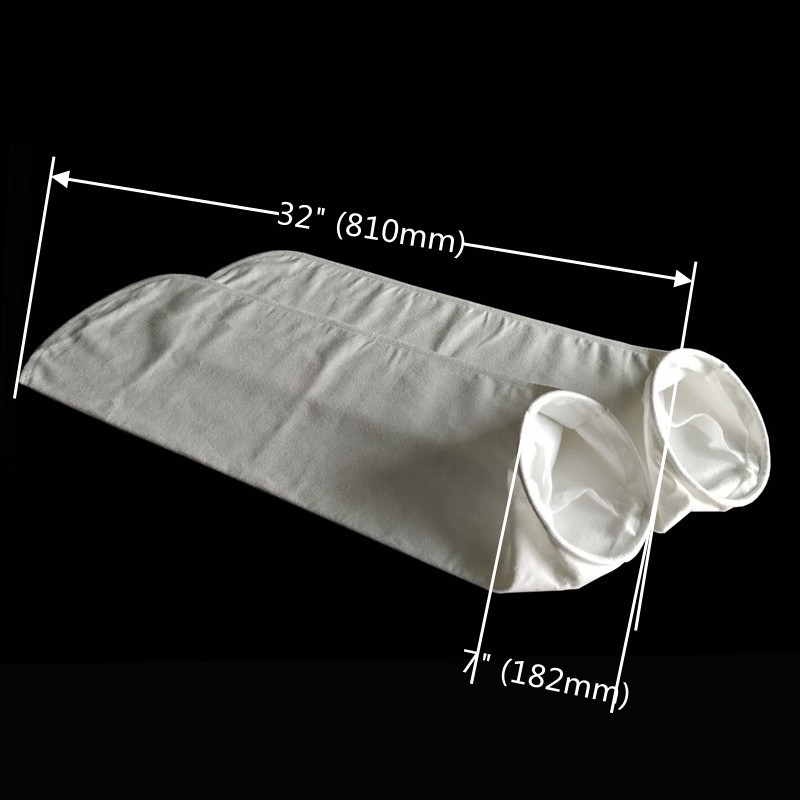

# 02 |

7″ (177.8mm) |

32″ (812.8mm) |

40m3/h |

0.5m2 |

17.0 L |

|

# 03 |

4″ (101.6mm) |

8″ (203.2mm) |

6m3/h |

0.09m2 |

1.30 L |

|

# 04 |

4″ (101.6mm) |

14″ (355.0mm) |

12m3/h |

0.16m2 |

2.50 L |

|

# 05 |

4″ (101.6mm) |

20″ (508.0mm) |

18m3/h |

0.2m2 |

3.80 L |

| Material |

Work Temperature |

Micron Retention Ratings Available |

|||||||||||||

|

0.2 |

0.5 |

1 |

5 |

10 |

25 |

50 |

75 |

100 |

150 |

200 |

250 |

300 |

400 |

||

|

PO |

<80℃ |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

PE |

<120℃ |

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

POXL |

<80℃ |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

PEXL |

<120℃ |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

NOMEX |

<200℃ |

|

|

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

PTFE |

<260℃ |

|

|

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Bag Filter and Cartridge Filter proved to be most effective in following applications due to easy handling and cost effective as compared to other traditional system likes filter press & self cleaning system.

We have a wide choice of filter medium from 0.5 micron to 1,200 micron, different material composition likes PP, PE, Nylon to ensure its Chemical compatibility.

High quality control in our construction of filter bag ensure no fiber migration during filtration process and no contamination to your liquid.

- Chemicals Filtration

- Petrochemicals Filtration

- DI Water Application in Semiconductors & Electronic Industry

- Food & Beverage

- Fine Chemicals Filtration

- Solvent Filtration

- Edible Oil Filtration

- Adhesive Filtration

- Automotive

- Paint Filtration

- Ink Filtration

- Metal Washing

If you have any question or we can be any further assistant, please do not hesitate to contact us.

Contact us: Tel: +86-21-59238005 Email: sales@precisionfiltrationsh.com or vivi@precisionfiltrationsh.com

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for China Wholesale Filter Bag Supplier Suppliers – PTFE Filter Bag – Precision Filtration , The product will supply to all over the world, such as: Puerto Rico, Washington, Thailand, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.